Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

n-butyraldehyde

As a follow-up to the successful synthesis of benzaldehyde with persulfate I attempted a similar synthesis of n-butyraldehyde to see if a similar

success could be achieved with an aliphatic primary alcohol.

Results

In summary it was a complete failure.

Experimental

A 3-neck 500mL RBF was equipped with a Claisen adapter and a thermometer. Attached to the Claisen was a pressure-equalizing dropping funnel and a

water cooled reflux condenser. The RBF was placed on a heating mantle resting on a magnetic stirrer.

The RBF was charged with 18.3 mL (0.2 mole) of n-butanol and 100 mL of H2O, with vigorous stirring. The dropping funnel was charged with 46.7g (0.2

mole) of Na2S2O8 dissolved in 150mL of H2O. The temperature of the pot was brought up to about 70C. The oxidant was then dropped in at several

drops/sec. Nothing seemed to be happening so the temperature was raised to about 90C and the addition of oxidant continued. Eventually small drops

of an oily looking liquid began appearing on the upper part of the RBF and the mix turned a little yellow. The pungent citrus smell of the aldehyde

was very much present. Toward the end the mix seemed to be self-heating but at no time did it threaten a runaway.

The reaction mix was allowed to cool then shaken with 25mL of DCM in a 500 mL separatory funnel. The heavy organic (tinted light brown) was drained

off and 2 scoops of anhydrous MgSO4 added for drying.

The decantate was fractionally distilled using a broken glass packed Hempel column. The 25mL of DCM came off nicely just below 40C. Then the

temperature rose up to 77-90C in an unsteady fashion. Normal bp for n-butyraldehyde is 75.7C. Only 1-2mL of cloudy distillate was caught in the

receiver. It gave a positive Tollen's test.

Conclusions & Discussion

This methodology, successful for benzaldehyde, plainly was not successful for n-butyraldehyde. Is this the difference between a benzylic alcohol and

a primary aliphatic alcohol? It seems so.

As a comparison, I have an old school procedure (Brewster) for making n-butyraldehyde. It adds the alcohol to the dichromate/sulfuric acid at 70-90C

and relies on the volatility difference of the alcohol vs the aldehyde to drive off the aldehyde vapor for immediate condensation. I have tried this

also. My yield here was a little better but still very poor.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Ah great to see someone doing what its really all about - theres only a few of us left - people who are actually doing science because they enjoy it!

Pleasure reading your write-up Magpie! Buteraldehyde is soluble in water, 8.4grams in 100ml at 25C - at 70C should be more. This supports the idea

that its the solubility difference that was giving the yield with benzaldehyde. The definitive test would be to separate out the butyric acid (by say

adding CaCl2) and weigh, if there's a good yield of that, theres the proof.

Will you do a write-up of your aldegyde work whenyou finish?

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Ah - where did the aldehyde go? If it went to the acid, you should have smelled that. Even if it was chopped to shorter chain acids through attack

of the alpha hydrogens, that should have had a distinctive smell. As Len suggested, it should be possible to work up the residue to obtain the

acid(s). Not sure if CaCl2 is the best for salting out, need to check references.

I've done n-butanol to butyraldehyde using the distill from oxidising mixtures, both dichromate and MnO2, dripping the alcohol into the hot mix.

Yields were never great, 30 to 40 percent.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

By not_important:

| Quote: |

Ah - where did the aldehyde go?

|

That is a good question. I don't smell any significant odor of butyric acid, presuming it is a foul odor of putrefied butter. When I smell the

residual in the pot (5 mL or so) it smells of the aldehyde. The packing in the column looked like it was drenched in aldehyde and there was a good

reflux going. I think part of my problem could be that the batch size was just too small. By the time you get the column loaded there is not much

left in the pot. That probably caused the erratic temperatures at the still head after the DCM came off.

I'm planning on trying to salvage the aldehyde in the residue using NaHSO3.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I made up about 23 mL of saturated aqueous NaHSO3 solutiion and shook it with the pot residue. No adduct ppt formed. Just a two phase liquid with

the dark organic floating on top. It still smells like adehyde, however. Unless someone has a better suggestion I'm ready for a little waste

management.

|

|

|

PainKilla

Hazard to Others

Posts: 306

Registered: 29-4-2004

Member Is Offline

Mood: No Mood

|

|

I have found that a straight solution of aldehyde along with NaHSO3 does not form the adduct as well as a solution of the aldehyde in toluene (say

20-30% w/v).

The reaction is fairly quick, but I would let it stir (vigorously) for at least a few hours...

Anyway, I hope this helps and works.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Good work Magpie! A pleasure to read as always!

I think the bisulfite test is most effective for benzylic aldehydes, and methyl ketones. Maybe the adduct does form (in part), but is soluble to a

greater extent in water.

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Aldehydes in general are good at forming bisulfite adducts, unless they are sterically inhibited. However you need a definite excess of NaHSO3 to

force the reaction to completion, and small aldehydes and ketones form fairly soluble adducts. For example, the org-syn prep of hexaldehyde uses 100

g NaHSO3 in 300 cc water, which while not saturated is fairly close to that, to form a water solution of the aldehyde (roughly 50 grams worth)

http://www.orgsyn.org/orgsyn/orgsyn/prepContent.asp?prep=cv2...

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

@len: I don't have any plans to for an "aldehyde write-up." My intent is just to describe these experiments in enough detail that they could be

reproduced by anyone.

@PainKilla: I added ~ 7mL of toluene and shook. No change.

@not_important: Yes I had an immediate and striking formation of adduct with my benzaldehyde without even being very careful. With this supposed

n-butyraldehyde I made up 23mL of a 40% solution of NaHSO3. With no more than 5mL of aldedhyde present I feel I had a good excess. I even cooled it

in ice water after addition.

I feel I am beating a dead horse here. It smells like the aldehyde but it is not proving out. Thanks for all the suggestions.

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Magpie, given you noticed no butyric acid smell (that smell can't go unnoticed) it might be worth trying some modifications before giving up. Consider

that the activation energy for radical oxidation of butanol is much higher than for benzyl alcohol (the bond dissociation energy for PrCH(OH)-H is

about 12 kcal/mol higher than for PhCH(OH)-H). Thus the temperature where the oxidation runs at an appreciable rate should be considerably higher. At

a higher temperature you can expect some Na2S2O8 to decompose and thus contributing to the presence of some starting material in the distillate. If

you still have motivation you could try out using some excess Na2S2O8 (~ 1.5 eq) and maintaining the temperature at ~90°C with a water bath during

the addition of the oxidant, but doing this in a distillation setup so that the butyraldehyde/steam could distill over with the aid of the exothermic

reaction heat (then after adding all Na2S2O8, heating to boil to distill all the product). Unfortunately some butanol will steam distill over with the

product, but not much since it is relatively soluble in water.

It would also be interesting to try out adding 1mol% of some one electron oxidant metal cations for the possible catalysis (Ag, Ce, Co salts, for

example). Hydrogen abstraction might proceed faster if mediated with species like Ag(II), Ce(IV) and Co(III) rather than Na2S2O8 itself (though

possibly, side reaction would also go faster – especially Ag(II) species are too reactive).

The bisulfite adduct of butyraldehyde, like all such bisulfite adducts, should be prepared in as concentrated ethanol solution as possible since many

bisulfite adducts are too soluble in water to form a precipitate (contrary to common belief most bisulfite adducts are water soluble). Generally, one

dissolves NaHSO3 in as little water possible, then dilutes with about 5-10 times as much EtOH and if some precipitates again, adds the minimum water

needed to redissolve the NaHSO3. This solution is then used in at least twofold excess over the carbonyl compound – at least that is how I used to

do it, and it always worked. With aldehydes the adduct forms in a couple of minutes, but alkyl methyl ketones need more time, sometimes with warming

up to speed up the precipitation.

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

When I was learning about the properties of aldehydes at school we partially oxidised some propan-1-ol to propanal. the method follows:

Place about 10ml of dilute sulphuric acid (was either 1M or 2M) in a flask and add about 3g of sodium dichromateamd 2-3 anti-bumping granules. Swirl

the contents of the flask until solution is complete.

Add 1.5ml of propan-1-ol in drops from a dropping pipette, swirling the flask as you do so to mix the contents, and then equip the flask with a

stillhead and receiver adaptor.

Gently and slowly distil about 2ml of liquid into a test tube, taking care that none of the reaction mixture splashes over.

We also had a practical assessment in which we were to identify an alcohol by boiling point, and some of the reactions of the oxidation products (like

testing with qualitative benedict's reagent for futher oxidationablility (is that a real word?). I myself came to the conclusion that I had ethanol

and I was correct, but there was also someone in the class with butan-1-ol, and I cant remember smelling anything particularly nasty (similar to the

description of butanoic/butyric acid, and so I assume that the aldehyde was the major product.

I know this method requires the use of dichromate but I thought it might be helpful to post incase someone has access to a dichromate, or maybe the

proportion of oxidising agent : alcohol can be taken from the procedure and adapted for persulphate or another oxidising agent.

[Edited on 1-5-2008 by DJF90]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Nicodem says:

| Quote: |

At a higher temperature you can expect some Na2S2O8 to decompose and thus contributing to the presence of some starting material in the distillate. If

you still have motivation you could try out using some excess Na2S2O8 (~ 1.5 eq) and maintaining the temperature at ~90°C with a water bath during

the addition of the oxidant, but doing this in a distillation setup so that the butyraldehyde/steam could distill over with the aid of the exothermic

reaction heat (then after adding all Na2S2O8, heating to boil to distill all the product).

|

I find it interesting that you are recommending an excess of oxidant because that is what Brewster (1960) also specifies. He provides the following

stoichiometry:

3CH3(CH2)2CH2OH + Na2Cr2O7 +4H2SO4 --->

3CH3(CH2)2CHO + Na2SO4 + Cr2(SO4)3 + 7H2O

Then, in the procedure he specifies 149g (0.5mole) of Na2Cr2O7, yet only 37g (0.5mole) of n-butanol. So, in effect, he specifies oxidant at 300 mole%

of the stoichiometry!

Brewster specifies holding the oxidant/acid/water mix at 75-90C while dripping in the alcohol. The intent is to immediately distill over the

aldehyde, as you recommend.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Nicodem, i would try using Fe2+/Cu2+ salts in place of Ag+ or Co2+, as they would be much cheaper/avaiable, and their use has been patented for

oxidation of benzylic methyls/alcohols.

Maybe they could speed the reaction up enough for the aldehyde to steam distill as soon as formed, much more so than the starting compound. I think

they also had a role in preventing further oxydation of the formed aldehyde; trilobite posted a very complete and interesting article on the mecanisme

of persulfate oxidations in the TCCA benzylic oxidation thread.

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Magpie:

reference - 100 g NaHSO3 to 50 g C6 aldehyde, 50% longer chain than your case, adduct is fully in solution.

you - ~9 g NaHSO3 to 5 g C4 aldehyde. You have a lower ratio, and the adduct should be even more water soluble.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks for the reference data, not_important:

| Quote: |

reference - 100 g NaHSO3 to 50 g C6 aldehyde, 50% longer chain than your case, adduct is fully in solution.

you - ~9 g NaHSO3 to 5 g C4 aldehyde. You have a lower ratio, and the adduct should be even more water soluble.

|

Instead of guessing I will quote from my notebook:

"About 10mL of n-butyraldehde-like smelling brown liquid left in pot. Decided to treat with NaHSO3 to form adduct.

moles aldehyde assumed: (10mL)(0.817g/mL)/72.11 = 0.113; g NaHSO3 = 0.113(104.06) = 11.79g Use 15g for excess. To make 40% soln (saturated) used

23.9 mL water and 13.63g Na2S2O5."

So that is what I did. If you think the adduct may still be in solution then possibly you are correct. I still have it.

I will run a test. I will withdraw 1 mL of the aqueous solution and treat it with 5mL of saturated NaHSO3.

[Edited on 1-5-2008 by Magpie]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Consider what the adduct does:

Go from C=O to HO-C-SO3(+)

The HO- will increase water solubility some; n-BuOH 9.1/100 cc vs butyraldehyde 7/100 cc

the SO3(+) will greatly increase solubility, C6 sulfonic acids are water soluble.

Also the pH must be quite near neutral, even sodium bicarbonate will break up the adduct.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I ran the test as described above - no ppt formed. pH was 6.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

n-butyraldehyde via persulfate, 2nd try

This is my second attempt at making n-butyraldehyde using persulfate.

Results

This also was a complete failure. However, the results were so interesting that I dedided that they should be reported.

Experimental

178.6g of Na2S2O8 (0.75 mole) was dissolved in 500mL of water and placed in a 1000 mL RBF. The RBF was placed in a water bath on a magnetic

stirrer-hotplate. The single neck of the RBF was equipped with a Claisen adapter. One Claisen neck was fitted with a dropping funnel, the other a

distilling head-condenser-receiver. 18.5g of n-butanol (0.25 mole) was placed in the dropping funnel.

The water bath was heated to 85C and the system allowed to equilibrate, with stirring of the oxidant. The alcohol was then slowly dribbled in to the

pot. Nothing happened until about 10mL of alcohol had been added. Then everything took off. The pot started actively fizzing (maybe boiling) and

the distillation head temperature shot up as high as 97C. About 20 mL of very clear single phase distillate was collected. Then everything settled

down and the temperature at the distillation head dropped as low as 35C.

The rest of the alcohol, some 12 mL or so, was slowly added. The water bath temperature was kept at 80-90C. No further reaction was apparent.

Conclusions & Discussion

Even though the oxidant was in a 200% excess, it seems as though it was spent following the one and only exotherm occuring early in the alcohol

addition. There was virtually no smell of aldehyde, or butyric acid. With all the fizzing that was occuring at the exotherm I'm wondering if

everything got chewed up to CO2.

I feel it was a mistake to heat all the oxidant at once. However, this is the method Brewster used with dichromate/sulfuric acid, where he also drips

in the alcohol. He also uses 3X the oxidant called for by stoichiometry. I was trying to model Brewster's method only substituting persulfate for

dichromate/sulfuric acid.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Magpie

I ran the test as described above - no ppt formed. pH was 6. |

I'd be surprised if it did as from what I've read, and as I've been saying, the bisulfite adduct is soluble in water.

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Magpie, using the wrong addition order is not a particularly good idea. This oxidation has nearly nothing in common with the dichromate one with which

you compared it. The only resemblance is in the glassware setup, but the mechanism is completely different. The persulfate solution starts decomposing

at such high temperature so it is not just to prevent such runaways that you should be using the normal addition order. I do not know what happened,

but it sounds like autocatalysis (like oxidation by a radical chain reaction), perhaps really leading to something as full oxidation to CO2. I'm glad

you did not have glassware mishaps as ten ml of butanol's total oxidation is a lot of energy for such a setup.

Have you read what me and not_important told you about the bisulfite adducts? You can not form it the way you are doing it. Try the general method (I

think it is described in Vogel's, Organikum or any such handbook).

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

Have you read what me and not_important told you about the bisulfite adducts?

|

Yes, I see what you (both) are saying. I will give this synthesis another shot. This time I will follow the recommendations of Nicodem.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I have been doing some further research, mostly, on a small scale so that I can better understand the oxidation of n-butanol with sodium persulfate.

My small scale testing has been done at 0.5 mL of n-butanol using test tubes. I hope this does not become too tedious to the reader.

Experiment A

Three test tubes were each loaded with 0.5 mL n-butanol. Aqueous sodium persulfate (1.3g/4.1mL) was added at 1X, 1.5X, and 2X stoichiometry,

respectively. The tubes were placed in a boiling water bath. Somewhere around 90C the rxn would "ignite," with bubbling, the clear mix would turn

milky, and a slightly yellow oil, smelling of aldehyde, would float to the surface. Upon standing, for a day, the 1X smelled of aldehyde, the 2X

smelled of butyric acid, and the 1.5X smelled "in between."

From this I conclude that the stoichiometric amount of persulfate is probably the most appropriate.

Experiment B

This was done in response to the findings of the Chinese paper provided by kmno4 in the benzyl alcohol thread. The results looked "too good to be

true" but the experiment was easy to run so I tried it. Essentially, it called for mixing 1 mmol of n-butanol, and ammonium persulfate at 1.5X

stoichiometry, at high dilution with water, hold at 30C for 2 hours with stirring.

I tried to mimic this reaction using 9.25g (0.125 mole), 250mL H2O, and a water bath to hold at 30C with stirring for 2 hours. Nothing happened.

Rather than just throw the reactants away, I added them at 5-10 drops/sec into an RBF in a water bath held at 90C. Aldehyde was formed. I then steam

distilled the products for a recovery of 2mL of what appears to be fairly pure n-butyraldehyde.

Experiment C

I really wanted to know the temperature at which "ignition" takes place. So again 0.5 mL of n-butanol was mixed with a stoichiometric amount of

aqueous Na2S2O8 in a test tube. The alcohol did not all dissolve probably mostly because the water was saturated in the oxidant salt. The tube was

then placed in a boiling water bath and the temperature carefully monitored as it increased. The "ignition" temperature was right at 90C. Even

though the reactants were at 90C, the reaction would only take place when stirred, as the alcohol continued to float on top. As the alcohol reacted,

a yellowish oil would form and float on the brine. The smell of aldehyde was present.

Conclusions & Discussion

I now feel that I know the conditions needed for this reaction to proceed in decent yield with virtually no formation of butyric acid. Doing this

using a satisfactory amount of n-butanol, ie, at least 20mL, without having a dangerous runaway is the tricky part.

Another problem is dealing with all the water necessarily added to keep the sodium persulfate in solution. This complicates recovery of the aldehyde

in the workup. This could be mitigated by using ammonium persulfate as it is twice as soluble as sodium persulfate.

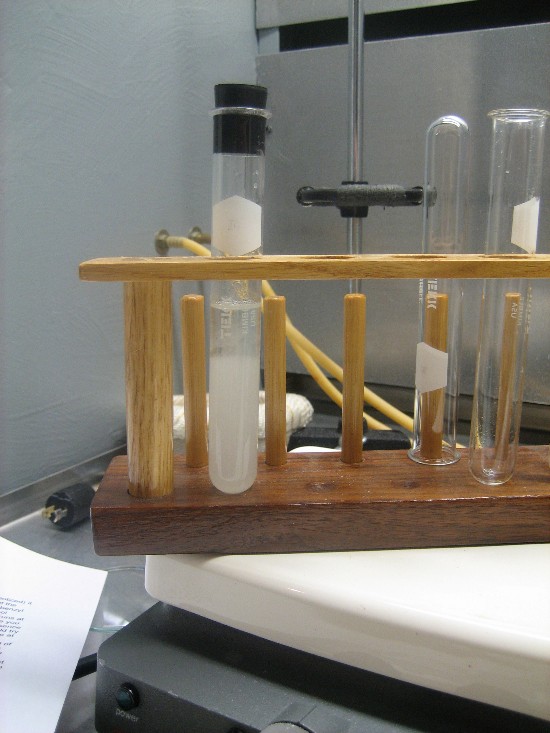

Edit: Bisulfite Adduct

Feeling like I needed confirmation of the identity of my aldehyde smelling product, I decided to try and form the bisulfite adduct using the method of

Nicodem. At first no ppt appeared. Then just as he said after about 2 minutes a haze started to appear. Then slowly more of a very fine ppt formed

as shown in the picture below. This ppt is very different in nature to that easily formed with my synthesized BzH. Needless to say I was very happy

to see this positive result after all the experiments I have done to make n-butyraldehyde.

[Edited on 7-5-2008 by Magpie]

[Edited on 7-5-2008 by Magpie]

[Edited on 7-5-2008 by Magpie]

[Edited on 7-5-2008 by Magpie]

|

|

|

Siddy

Hazard to Self

Posts: 81

Registered: 8-10-2007

Member Is Offline

Mood: No Mood

|

|

41g n-butanol to 13g n-butraldehyde

Only 30% yield but atleast it works

|

|

|

Siddy

Hazard to Self

Posts: 81

Registered: 8-10-2007

Member Is Offline

Mood: No Mood

|

|

sorry, the attachment thingy didnt work

http://img368.imageshack.us/my.php?image=s3rdpage320321mk8.j...

|

|

|