| Pages:

1

..

5

6

7

8

9

..

14 |

4-Aminophenol

Harmless

Posts: 3

Registered: 4-4-2009

Location: Germany

Member Is Offline

Mood: No Mood

|

|

This is my Leadphosphate:

First I refluxed 169 g elemental lead with 113 ml of 65% Nitric Acid.

Than I dissolved the whole precipitate of Pb(NO3)2.

Now I dissolved 133 g of sodiumphosphate in Water, and added the solution to the Pb(NO3)2. I immediately received a white precipitate of Pb3(PO4)2. At

least I filtered, washed with H2O and dryed the leadphosphate.

|

|

|

chief

National Hazard

Posts: 630

Registered: 19-7-2007

Member Is Offline

Mood: No Mood

|

|

How about using lead directly as anode in a chlorate cell ? Lead chloride as well as chlorate are insoluble, as well as lead hydroxide, oxide etc. .

Any residual Lead-salts could be ppt. by adding as much as necessary Na2SO4-solution.

From the Pb-containing slurry of the bottom of the cell then Lead-salts could be made with weaker acids .... . The dissolution would be powered by the

anodic oxidation and would be quicker ... ?

|

|

|

chief

National Hazard

Posts: 630

Registered: 19-7-2007

Member Is Offline

Mood: No Mood

|

|

A question would be if Pb-chlorate/perchlorate (if formed at all) might be a dangerous primary ... ?

Maybe even by regaining the Pb from the slurry (near 100 %), by heating with C, there could a Pb-Anode-cyclus be established, that would be quite much

easier than the tedious plating of PbO2 onto graphite ... ?

As mentioned above any Pb can be ppt. out using Na2SO4, since PbSO4 is one of the most insoluble salts (from the standard acids) known to man. Only

time is needed, to let the ppt. settle, and the rest of the solution will have maybe 1 mg/l or less of Pb.

With hot H2SO4 there is said to be some solubility of PbSO4, but thats no real wonder ...

Boiling the PbSO4 with conc. Soda-solution would most probably lead to PbCO3 ... ; maybe the others would react the same way: Hydroxide, dioxide ?

Then this would be the best way to operate on the slurry, since the PbCO3 would be most useful for preparation of other salts ...

[Edited on 5-4-2009 by chief]

|

|

|

no1uno

Harmless

Posts: 30

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Hmmmmmmmmm, bugger.... Ok, how to increase the solubility of the easily made lead salts (ie. those which can be made with the least effort and most

accessible chemicals)?

Perhaps this might help:

| Quote: | Description of the Leaching Process

The leaching process was developed by the Doe Run Company, independently of this research. This work has not been published in the open literature and

is therefore summarized here. The process consists of contacting finely ground mattes and slags with a hot, saturated acidic brine solution containing

approximately 25g/L ferric chloride. Ferric chloride serves to oxidise and solubilize metallic sulfides and is reduced to ferrous chloride in the

process. Hot, saturated sodium chloride brine is employed to increase the solubilization of lead. Lead chloride is quite soluble in sodium chloride at

elevated temperatures (~ 70g/L at 90C) whereas it has very low solubility (less than 1g/L) under conditions of low temperature and low chloride

concentration

Taken from the Encyclopedia of Chemical Processing: http://tinyurl.com/d7yp9q |

Does anyone have any lead chloride so they can check this? I have fuck all...

But it looks interesting, HCl is not exactly hard to get, NaCl, well....

Lead sinkers are everywhere (the dull coating on them is the carbonate usually)...

Use sodium hydroxide/carbonate to precipitate the lead hydroxide and then we could reuse the brine.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Strong solutions of alkali chlorides do somewhat increase the solubility of PbCl2, but not a great deal. Check the available books of solubilities.

Strong hydrochloric acid does better at increasing the solubility.

Lead is above hydrogen in the electromotive series, and will dissolve fairly quickly in non-oxidising acids if the resulting salt is soluble. Thus

powdered lead dissolves in HNO3 and hot acetic acid, and in hot concentrated hydrochloric acid. A clever girl can use a lath to prepare lead

turnings, or rid some wood rasps with a motor to ream off lead granules. Slowly add these to strong hot hydrochloric acid until it seems that the

lead has stopped reacting, then cool and chill the solution, followed decanting and filtering off the PbCl2. The acid can be brought back up to

strength and reused with further additions of lead.

Passing moist CO2 over lead turnings will slowly convert them to a basic lead carbonate. The Dutch process for white lead is based on the use of

fermentation to produce CO2 and acetic acid, which react with metallic lead to form a basic carbonate containing a small amount of basic acetate.

|

|

|

chief

National Hazard

Posts: 630

Registered: 19-7-2007

Member Is Offline

Mood: No Mood

|

|

It's much easier to increase the surface of the lead: Just melting it and letting it drop into water will give grains with more or less flattened

fringes. No mechanical dealing necessary.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

I've had poor luck with mossy lead, there were always appreciable amounts of thicker sections that were slow to react, whereas the turnings reached

rapidly. But you're correct in saying that it's easier to make mossy metals than to machine them.

|

|

|

einstein(not)

Hazard to Self

Posts: 50

Registered: 14-12-2006

Member Is Offline

Mood: No Mood

|

|

After a quick scan of the thread I haven't been able to find any info on what I might have made. If I missed it I apoligize in adavance.

100 grams Lead Dioxide and 100ml of glacial acetic acid were refluxed for 2 hours. Strong smell of acetic acid is gone from the clear liquid

covering a brownish residue that appears to be equal in volume to the lead dioxide. At first I didn't think anything had changed but the lack of

strong acetic acid smell must mean something did. Right?

|

|

|

Taoiseach

Hazard to Others

Posts: 241

Registered: 16-3-2008

Member Is Offline

Mood: No Mood

|

|

Anyone here who knows how to make lead nitrite, Pb(NO2)2?

I think I have accidentally made this already from NH4NO3 and Pb metal. I obtained a deep yellow solution. Adding a few drops of HNO3 and heating

would make it colourless again.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

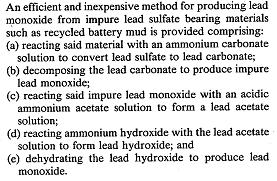

Lead Carbonate from Lead Sulphate + Ammonium Carbonate

Hello,

Anyone any comments to make on this patent. Lead Sulphate is easy to come by in old batteries. Does the Sulphate from old batteries contain any

Antimony Sulphate?

EDIT:

From another thread(after U'ingTFSE):

have done this reaction to get lead acetate from old batteries. It does work but you have to grind the sulphate and boil it with lots of carbonate.

Even then you don't get complete reaction but, if you settle or filter off the carbonate/sulphate mixture and leach it with acetic acid the carbonate

disolves and you can repeat the process with the leftover sulphate.

Dann2

Attachment: US4220628.pdf (247kB)

This file has been downloaded 719 times

[Edited on 5-5-2009 by dann2]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

PbO can be had by heating PbO2. I never actually seen this discussed but may have missed it.

Pb02 can be had from old Lead Acid batteries and should be fairly pure.

Will this PbO be difficult to get to dissolve in Nitric acid. I have read that it is difficult compared to PbO made by other chemical methods.

There is an article in References and translations needed(6) dated 21/2/10 (today) if anyone is interested.

Dann2

[Edited on 21-2-2010 by dann2]

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

Today I made several long ingots of lead (from car batteries, lead seals, etc, all from scrapyard.. That should have some antimony , bismuth, etc but

Im not very worried with it)

Tried to follow the info from patent US626330 "Process of Producing Peroxid of Lead". Used two Pb ingots, one as anode and the other as cathode. Used

~800mL of tap water, 2 teaspoons of homemade recristalized NaClO3 (containing some chloride) and 10 teaspoons of technical grade ammonium sulfate. +5V

from PC PSU is already working on it. I dont know how many amps/current density because my multimeter is 'dead', but the electrodes are close, so I

guess a decent current should be passing through it).

The anode is rusting and forming some white spots on the PbO2 layer but the electrolyte is clean, no PbO2 flaked in about 1 hour of electrolysis.

The only thing the patent did that I dont was bubbling air through the solution.. Maybe , I guess, that is just for stirring/flaking purposes, but I

may be wrong.

Just for comparision, Im already doing a similair experiment but using plain NaCl as electrolyte (~100/L). When turning on power supply, winthin

seconds appeared a rusty cloud on electrolyte.. And the PbO2 continues to flake off...

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Quote: Originally posted by Aqua_Fortis_100%  |

<snip>

Just for comparision, Im already doing a similair experiment but using plain NaCl as electrolyte (~100/L). When turning on power supply, winthin

seconds appeared a rusty cloud on electrolyte.. And the PbO2 continues to flake off...

|

Interesting. That was my experience also, although with fairly pure lead. Is it the alloy, or is lead (metal) suitable in chlorate solutions?

Tim

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

Now the container with NaCl electrolyte have a decent layer of PbO2 on the bottom and the electrolysis keeps going.

| Quote: | | Is it the alloy, or is lead (metal) suitable in chlorate solutions? |

Do you refer to chlorate -> perchlorate conversion? I dont tried ..But I have a 'feel' that this process wont work and if works, then will have

poor eficience and will be messy. Maybe a little chloride in the home NaClO3 will be beneficial to make again PbO2 layer as it flake off.. Or maybe

just chlorate will do, but havent tried this also.

In my ammonium sulfate/NaClO3 electrolyte is ppting a white substance,probably some sort of lead hydroxide, but almost none PbO2. So I think patent

info dont works as described (unless the bubbling air step is really essential, but they didnt mention that)

[Edited on 22-2-2010 by Aqua_Fortis_100%]

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Quote: Originally posted by Aqua_Fortis_100%  |

Do you refer to chlorate -> perchlorate conversion? I dont tried ..But I have a 'feel' that this process wont work and if works, then will have

poor eficience and will be messy. Maybe a little chloride in the home NaClO3 will be beneficial to make again PbO2 layer as it flake off.. Or maybe

just chlorate will do, but havent tried this also.

In my ammonium sulfate/NaClO3 electrolyte is ppting a white substance,probably some sort of lead hydroxide, but almost none PbO2. So I think patent

info dont works as described (unless the bubbling air step is really essential, but they didnt mention that)

|

Ahh, then I misinterpreted this statement:

Quote: Originally posted by Aqua_Fortis_100%  | T

The anode is rusting and forming some white spots on the PbO2 layer but the electrolyte is clean, no PbO2 flaked in about 1 hour of electrolysis.

|

If current were high, it would be interesting, but without a multimeter, you can't measure it accurately. Since it is forming a white skin (I would

guess PbSO4), I take that to mean it's not working very well at all now?

Tim

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

Oh sorry.. You is right.. I forgot that sulfate (lead-loving) ion was in solution, so cant be lead hydroxide.. The current keeps going, and the

electrolyte have a temperature of about ~50°C.

| Quote: |

If current were high, it would be interesting, but without a multimeter, you can't measure it accurately. Since it is forming a white skin (I would

guess PbSO4), I take that to mean it's not working very well at all now?

Tim

|

It dont forms a skin but some weird 'blobs'/clusters in some points of the anode, probably this is the reason that anode is still able to delivery

current in solution.

Im wondering if the electrolytic method for producing carbonate/basic carbonate involving electrolysis in nitrate solution with CO2 bubbled through

(already mentioned in some patent cited earlier) could really work well at home.

Im wanting somewhat pure that I can readily react with any acid (acetic, nitric, etc) without letting anything undissolved.

I have about a kilo of a mix of lead oxides, made few years ago from molten Pb + molten nitrate method.

http://i242.photobucket.com/albums/ff176/tnitrato/P9060068.j...

At time I was specting just nitrite and PbO, but reacting the well-washed/dried "PbO" with HCl gave chlorine that proved to have some PbO2/Pb3O4, etc

in it..

So Im wondering if electrolytical methods will really give good products.. I dont think attempting PbCl2 route again since this salt has poor

solubility, and therefore to purify it needs lots of hot water (I hate manipulating large amounts of water ahaha)

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

I've done that before, using chlorate. The transient species, lead chlorate, is soluble, and doesn't crystallize, so it isn't an explosion hazard.

White Pb(OH)2 is the primary product. Without using a seperated cell and CO2 bubbler, you get some reduction of chlorate and lead, which should form

an impurity of PbCl2 and lead sponge when it plates on the cathode, which is a nuisance.

Calcining the Pb(OH)2 produces a yellow to drab orange product, which should be PbO with some Pb3O4. I have never been able to produce bright orange

Pb3O4 thermally.

Recrystallizing PbCl2 from hot water isn't so bad. You can reuse the water, it just takes a lot of passes.

Tim

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Quote: Originally posted by 12AX7  |

Recrystallizing PbCl2 from hot water isn't so bad. You can reuse the water, it just takes a lot of passes.

Tim |

Indeed. I'm under the impression, however, that it readily co-crystallizes with other lead halides. I had a mother liquor with traces of iodide (aka:

my lead waste bucket) and I dropped out a crop of fairly white PbCl2. Double recrystallization from boiling distilled water did not seem to reduce the

yellow tinge.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

turd

National Hazard

Posts: 800

Registered: 5-3-2006

Member Is Offline

Mood: No Mood

|

|

Co-crystallization is a strange term in this context. It probably grows crystals of PbClI, a known compound (not a solid solution). Would be

interesting to check under the microscope if there are different kinds of crystals or if this is really something like a solid solution with partial

replacement of Cl by I.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello AF100%,

Good to see you posting again!

There is a patent attached for making Lead Monoxide from not very pure Lead Sulphate. May be useful.

[Edited on 22-2-2010 by dann2]

Attachment: US4220628.pdf (247kB)

This file has been downloaded 663 times

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

My chlorate/sulfate cell continues to, very slowly, produce some contaminated PbSO4. Some lead found their way in the cathode and formed a very thin

lead sponge.

And in the chloride cell I scraped the anode and reverted the polarity on electrodes just trying to give a equal wear on both electrodes and produce

more PbO2... But tomorrow I should stop the electrolysis since I will need the power supply.

Quote: Originally posted by 12AX7  |

Calcining the Pb(OH)2 produces a yellow to drab orange product, which should be PbO with some Pb3O4. I have never been able to produce bright orange

Pb3O4 thermally.

Recrystallizing PbCl2 from hot water isn't so bad. You can reuse the water, it just takes a lot of passes.

Tim |

Not sure if this was discussed before (is quite a time when I have read most of this thread, actually all of it in that time), but in the book

Synthetic Inorganic Chemistry (fifth ed, pag 282) they describe the 'wet process' for producing Pb3O4, reacting PbO and PbO2 in basic solution, but

even with this method in the end you have to heat the product (~350-400°C):

| Quote: |

WET METHOD

Materials: lead monoxide (litharge) PbO, 33 grams = 0.15

F.W.

lead dioxide PbO2, 24 grams = 0.1 F.W.

6N NaOH.

Apparatus: 600-cc. beaker.

5-inch funnel.

150-cc. casserole,

iron ring and ring stand.

Bunsen burner.

Procedure: It is rather difficult to adjust the temperature successfully for the dry method. Place 33 grams litharge, 24 grams of lead dioxide and 50

cc. of 6 N NaOH in a 600-cc. beaker. Stir thoroughly and leave in a warm place (80°), striring when convenient and adding water whenever the mass

becomes dry, until the contents have become bright red. Finally wash the red lead thoroughly by decantation, and rinse on to a gravity filter in a

5-inch funnel. Let it drain over night. Lift the filter intact from the funnel, open it out on paper towels, and leave it on the hot plate until it is

entirely dry. Detach the red lead from the paper by bending the paper; transfer the dry material to a 150-cc. casserole and heat it in a flame about 2

inches high, holding the casserole in the hand and rotating it in the flame. At the correct temperature (350-400°) the material becomes a dark

reddish brown; after cooling it is a much more brilliant red than before heating. Great care must be taken to keep the material stirred during the

heating so that the under layers do not become superheated and changed to PbO. Preserve the preparation in a 2-ounce corkstoppered bottle.

|

I dont have any experience in playing with Pb3O4, but this substance seems interesting to have lying around (IIRC some crackling star compositions are

Pb3O4 based).

About PbCl2, I may try that, although Im now out of gloves

Tim, In your lead compounds page you seem to have a relevant work to manage liters of solution split in several pickle jars to purify PbCl2..(yeah DIY

glassware was and still will be also my only (real fun!) way of producing compounds..)

Thanks Dann2, Im also glad to see you again and even more glad to see the amazing patent you posted.

The most interesting part IMHO, is that the reaction between ammonium carbonate and lead sulfate is usually quite rapid (less than 1 hour and most

between 5 to 15 mins) and no heating is needed (actually I think heating probably cause part of ammonium carbonate being decomposed).

I only dont know if ammonium bicarbonate (more OTC here) is also suitable as direct reactant in place of carbonate. I was thinking in cautiously

heating the solution to remove excess CO2 and make normal carbonate, but Im worried if that wouldnt destroy a significant amount of the bicarbonate.

If ammonium bicarbonate cant be used, maybe just using slight excess of bicarbonate in dilute ammonia water should result in converting most in

ammonium carbonate.

BTW today I have visited a electronic components store to buy some diodes and as they have a trash specific for batteries, I asked to seller for some

of it. He was glad to gave me a plethora of NiCd, Ni-MHD, MnO2, etc baterries and among them was a small 6V lead-acid battery. This battery reminded

me instantly this thread.

[Edited on 23-2-2010 by Aqua_Fortis_100%]

[Edited on 23-2-2010 by Aqua_Fortis_100%]

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Quote: Originally posted by Aqua_Fortis_100%  |

in the book Synthetic Inorganic Chemistry (fifth ed, pag 282) they describe the 'wet process' for producing Pb3O4, reacting PbO and PbO2 in basic

solution, but even with this method in the end you have to heat the product (~350-400°C):

<snip>

|

Interesting. I am aware that PbO2(2-) and PbO3(2-) react, in fact I think it was in Brauer where, after a week or so, very large crystals are claimed

to be obtained (>2mm) from such a solution. It seems like that process is being used as a catalyst here, which is a fine way to go. I would

suppose you could reflux it as well, in which case you wouldn't have to add water, and it might go faster at ~100C.

Too bad about the final heating, though. 450-500C is pretty tight for "couple inch flame"...

| Quote: | | Tim, In your lead compounds page you seem to have a relevant work to manage liters of solution split in several pickle jars to purify PbCl2..(yeah DIY

glassware was and still will be also my only (real fun!) way of producing compounds..) |

Yup! I had recrystallized a satiny white product, 100g or so. Nice crystals, not very distinct in shape but the way they pile up is cool.

| Quote: |

BTW today I have visited a electronic components store to buy some diodes and as they have a trash specific for batteries, I asked to seller for some

of it. He was glad to gave me a plethora of NiCd, Ni-MHD, MnO2, etc baterries and among them was a small 6V lead-acid battery. This battery reminded

me instantly this thread.

|

Yay for cadmium!  Now you can destroy your kidneys even easier :rolleyes: Now you can destroy your kidneys even easier :rolleyes:

Tim

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

After decanting/washing several times Im now filtering the PbO2. Will treat it with some vinegar hoping to dissolve any oxide/hydroxide contaminating

PbO2, then wash again, then dry.. The yield seems good for a "quick'n'dirty" electrolysis.

And, yeah, I was wanting some lithium and nickel based batteries, but cadmium comes along with it.. But I have no use in mind for cadmium, at least

now

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

Cd is used in CdSe semiconductors (having a relatively low band gap voltage). I addition, a mixture of CdSe and CdS is used as a red paint pigment;

and CdS is used on its own as a yellow paint pigment. The metal itself is used in some low-melting solder alloys, with Sn and Pb.

[Edited on 23-2-10 by JohnWW]

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

Ive dried the PbO2 in the oven at 100°C but the brown powder contain some weird white granules. What can be? Pb oxide not leached by vinegar? Yield

is about ~20-25g.

The filter containing PbO2 in the pores was treated with dilute HCl and the chlorine smell was perceptible. After, the solution was treated with

excess baking soda and a small amount of a tan precipitate was filtered (but being a very small amount, I will just discard it in proper manner to a

battery recycling center as "lead carbonate").

JohnWW thank for the info. However, Im wondering what the home chemist can make with cadmium rather than pigments and solder alloys (and of course,

dont being poisoned). Some kind of catalyst for a crazy/interesting reaction, maybe? Or then another fun use, if any.

[Edited on 24-2-2010 by Aqua_Fortis_100%]

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

| Pages:

1

..

5

6

7

8

9

..

14 |