SupaVillain

Hazard to Others

Posts: 171

Registered: 28-10-2014

Member Is Offline

Mood: No Mood

|

|

Silicon Nitride Deposition (PVD)

Basically what im asking is, during magnetron sputtering will 25%argon/75%nitrogen gas change the composition of silicon nitride as it forms a layer?

In magnetron sputtering the plasma is etching away at silicon nitride sample and the molecules shoot out from it and onto a silicon wafer.

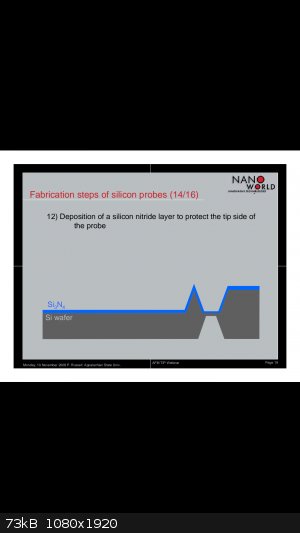

Im wondering if the nitrogen gas is going to be enough to turn the wafer's exposed layer into silicon nitride but im worried about that because my

application is for AFM probes so thin that once the silicon nitride layer is removed there wont be anything left...after reading this..."The material

(Si3N4) is prepared by heating powdered silicon between 1300 °C and 1400 °C in an atmosphere of nitrogen:

3 Si + 2 N2 → Si3N4

The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen"

[Edited on 3-2-2015 by SupaVillain]

|

|

|

SupaVillain

Hazard to Others

Posts: 171

Registered: 28-10-2014

Member Is Offline

Mood: No Mood

|

|

If the nitrogen gas, in combination with the plasma's temperature and effect wont be enough to synthesize Si3N4 out of the silicon wafer, then I think

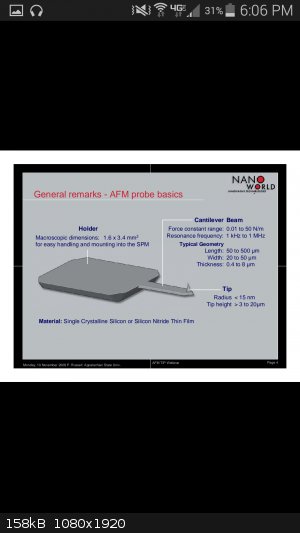

i can use it... but pure argon would be much better because of this. My application is these AFM probes....

|

|

|

DrMario

Hazard to Others

Posts: 332

Registered: 22-9-2014

Member Is Offline

Mood: Underpaid.

|

|

What you're talking about is "reactive sputtering" or "reactive PVD" as it involves a chemical reaction. The good thing about reactively sputtered

silicon nitride, is that you can control the stoichiometry of the SiNx film, therefore controlling things like compressive or tensile stress,

porosity, etc.

The bad thing about reactive sputtering for making SiNx films comes from the same thing that makes these films interesting: you will never have a

Si3N4 film with really good stoichiometry. For that you'd need low pressure chemical vapor deposition (LPCVD).

|

|

|

DrMario

Hazard to Others

Posts: 332

Registered: 22-9-2014

Member Is Offline

Mood: Underpaid.

|

|

FWIW, I've reactively sputtered tungsten nitride, and did play around with the nitrogen flow to change the properties of the film.

|

|

|