| Pages:

1

..

6

7

8

9 |

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

The solution started a light lime green colour.

It is going more Yellow/Gold.

|

|

|

kadriver

Hazard to Others

Posts: 196

Registered: 7-11-2012

Location: United States

Member Is Offline

Mood: Thankful

|

|

I just got done with the dissolution of the recovered foils video part 2. I've got the pregnant gold solution ready to precipitate (see photo)

The video is being uploaded to YouTube as I write this.

I had to make this a three part video in order to get this posted this morning.

I don't have ascorbic acid yet, it's on the way.

When it comes in I'll do part 3 showing the precipitation with the vitamin C (ascorbic acid).

The blue precipitate showed up again, I must say it does muck things up a bit. I don't think I'd use this process again because of the precipitate

that forms on day 4 or 5 of lifting the foils. It makes the process cumbersome extra long (not easy for a novice to deal with it).

But it was fun doing it for this video - it was 3 AM when I left my shop and I had to force myself to leave!

I used deltaH's process outlined above but scaled up to accommodate a full gram of pure gold.

That green color in the gold bearing solution usually indicates copper, nickel, or iron. I have some potassium thiocyanate that I can use to test the

solution after the gold is dropped.

I must say that this video would not have been possible without the gracious help given by deltaH and aga - Thank You!

kadriver

|

|

|

kadriver

Hazard to Others

Posts: 196

Registered: 7-11-2012

Location: United States

Member Is Offline

Mood: Thankful

|

|

OK, here is part 2 of 3:

https://youtu.be/TUxJ0YhATxM

kadriver

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Brilliant !

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

Wow kadriver, that was SO interesting! Great job

You know what? Now that I see it in all its glory, that cyan precipitate looks a helluva lot like copper hydroxide

Perhaps the pH climbed too high over the course of the whole dissolution and then it started precipitating. You might try putting a little in a test

tube and see if it dissolves in an excess of ammonia to form a clear deep blue solution, the copper tetraamine complex.

As for recovering that copper, you could maybe filter it under suction to concentrate it with a fine filter, then redissolve the resulting slime on

the filter paper in just enough HCl to do the job. Then you could boil it with ascorbic acid to reduce to copper metal.

When you do the copper reduction, use an excess of ascorbic acid and really boil down the solution so that you can reduce the maximum amount of it.

Don't worry about the reduced ascorbic acid crystallising when you boil it down, when it's done, just wash everything with water and it will

redissolve. I think the poor yields people get with copper reductions and ascorbic acid is because towards the end, the concentration of copper and

ascorbic acid is low and so the chemical kinetics is too slow, but if you boil it down, you keep concentrating it so it should drive it up an give

decent yields.

Very nice and well done again!

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

Copper chloride salts can also precipitate as a mixed copper chloride - hydroxide material, namely dicopper chloride trihydroxide, but this is

described as being slightly greenish.

https://en.wikipedia.org/wiki/Dicopper_chloride_trihydroxide

Maybe there's an acetate version.

UPDATE: Indeed there is, see this paper:

http://onlinelibrary.wiley.com/doi/10.1002/crat.201100262/ab...

[Edited on 15-10-2015 by deltaH]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Copper acetate maybe ?

https://en.wikipedia.org/wiki/Copper%28II%29_acetate

Seems historically it was made with acetic acid & copper sheets.

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

Copper acetate is reasonably soluble, hence why I suggested a mixed hydroxide, much more insoluble. Damn those crystals are pretty!

Hmm... maybe it is just the acetate after all if the vinegar precipitates it.

Either way, HCl should dissolve it quite quickly.

[Edited on 15-10-2015 by deltaH]

|

|

|

Little_Ghost_again

National Hazard

Posts: 985

Registered: 16-9-2014

Member Is Offline

Mood: Baffled

|

|

At around 1.11 in the video I see a large ring of deposit around the beaker, could it be with the bubbling as it dries on the side of the beaker you

are altering the chemistry?

You might be able to avoid the precipitate with some kind of pH control like dosing pump? Or simple very slow drip rate

Dont ask me, I only know enough to be dangerous

|

|

|

kadriver

Hazard to Others

Posts: 196

Registered: 7-11-2012

Location: United States

Member Is Offline

Mood: Thankful

|

|

I'll be heading to my shop after all-day appointments with ascorbic acid in hand.

The process used to dissolved worked perfectly.

What would be the procedure for precipitating the gold with the vitamin C?

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

You probably know most of this, but for others who might read it for the first time, I'll be more detailed:

Work out how many moles of gold you have in solution (I'll leave that as an exercise for you  ). You need a minimum of 1.5 times this of moles of ascorbic acid to reduce it, but I'd say use 2 to have an excess and

make sure the ascorbic acid doesn't limit the reduction, it's cheaper than gold after all ). You need a minimum of 1.5 times this of moles of ascorbic acid to reduce it, but I'd say use 2 to have an excess and

make sure the ascorbic acid doesn't limit the reduction, it's cheaper than gold after all  The molar mass of ascorbic acid is 176g/mole. The molar mass of ascorbic acid is 176g/mole.

People normally dissolve the ascorbic acid in a minimum amount of water (it's solubility is about 33g/100ml water) and then add this to the metal salt

solution with stirring, then boil for a while, then leave to stand to settle out.

Not so sure if this predissolving of the ascorbic acid is necessary, I'd add it straight in under stirring and then boil the solution.

After recovering your gold, check that the filtrate doesn't contain any dissolved gold with stannous chloride NOR that it's coloured. A coloured

solution might contain colloidal gold yet give a negative test for gold with stannous chloride!

PLAN B: If for some reason your gold doesn't settle out but remains as a coloured solution, then boil the solution right down to get a dry solid. You

can then scrape the solids out and simply burn off the reduced ascorbic acid containing the metallic gold in the crucible with a torch (it will char

first but then quickly burn off to nothing). The reduced ascorbic acid molecule is sugar-like so it will char to carbon and then burn quite easily.

Bert even commented that you can use it as solid rocket fuel

[Edited on 15-10-2015 by deltaH]

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

Oh forgot to add, after adding the ascorbic acid the gold solution, if you don't see an immediate colour change, try raising the pH with sodium

bicarbonate to about 7, but I doubt this will be necessary.

|

|

|

kadriver

Hazard to Others

Posts: 196

Registered: 7-11-2012

Location: United States

Member Is Offline

Mood: Thankful

|

|

Part 3 of 3

Thanks to you guys for helping me with this video!

https://youtu.be/CAhh6p4E6-I

kadriver

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

WOOOOOW I can't beleive the ascorbic acid works so well. I'm now happy for you that you bought a bulk bag of it!!!!!

Very nicely done kadriver! Pro video as always.

I think this is a first ascorbic acid reduction of gold on youtube AFAIK. Hopefully you'll get some extra viewership. Crossing fingers.

Thank you for the acknowledgement, I'm really honoured!

[Edited on 16-10-2015 by deltaH]

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

Looks like aga was right, that precipitate behaves like copper acetate, well done aga, you win 50 kudo's, don't

spend it all at once

Kadriver your recovery was 20% less this time, do you think this was because of gold not recovered properly by the process or just

less gold to start with in the fingers?

[Edited on 16-10-2015 by deltaH]

|

|

|

kadriver

Hazard to Others

Posts: 196

Registered: 7-11-2012

Location: United States

Member Is Offline

Mood: Thankful

|

|

Quote: Originally posted by deltaH  |

Kadriver your recovery was 20% less this time, do you think this was because of gold not recovered properly by the process or just

less gold to start with in the fingers?

|

Good observation. It is because there is still much gold foils left on the fingers. If the fingers had been left in the bubbler longer then the yield

would have been much higher, in fact possibly up around 1.1 to 1.2 grams.

The first batch I did, where I broke the 5 liter beaker, had actually continued to bubble for about three more days AFTER the thick precipitate showed

up. I just let it go for lack of knowing what to do next.

Then, after I removed the air hose, the fingers spent another 5 days just sitting in the precipitate until the beaker got broken, then ANOTHER day or

two until you emailed me asking about it!

The result is the one gram of pure gold that I got from the strainer from the broken beaker, PLUS another undetermined amount as unprocessed loose

foils still sitting at my shop, would have totaled well over 1 gram.

The yield from part 3 in this video only spent 90 hours (less than 4 days) in the bubbler. That is why I only got 0.8g of gold. There is probably

another half gram or so left on those fingers. I saved these fingers and will process them in acid peroxide until I get 100% of all the gold - I'll

let it go until each finger is totally stripped of gold.

I hope I've made it clear why this video part three yield was lower - it's because the fingers where not allowed to bubble longer which left foils

attached to the fingers.

I have learned so much from processing the fingers in this way. I was going to just go ahead and use copperas (ferrous sulfate) to precipitate because

I was ready to drop the gold but the vitamin C had not arrived - I'm glad I waited and followed the process you had in mind. I'm still wondering how

in the heck you came up with it!

There has been a tremendous gain in experience and knowledge for me from this and I owe much to you and aga - Cheers!

kadriver

|

|

|

kadriver

Hazard to Others

Posts: 196

Registered: 7-11-2012

Location: United States

Member Is Offline

Mood: Thankful

|

|

Quote: Originally posted by deltaH  | Looks like aga was right, that precipitate behaves like copper acetate, well done aga, you win 50 kudo's, don't

spend it all at once

|

I agree. If I had to do this over again, I would just add enough HCl to dissolve all the precipitate, then quickly and easily filter out ALL the foils

into a coffee filter.

kadriver

|

|

|

kadriver

Hazard to Others

Posts: 196

Registered: 7-11-2012

Location: United States

Member Is Offline

Mood: Thankful

|

|

Adjusting pH was done to minimize or eliminate chlorine gas when adding the bleach. It would be nice to know if buffering the solution prior to adding

the bleach worked to eliminate chlorine gas.

How can I test to see if it worked?

kadriver

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Smell it ! Chlorine has a distinct and strong smell.

Waft some of the air above the beaker towards you - don't just dunk your schnozzle right in there and take a big sniff.

Loving the videos.

Great job kadriver !

Edit:

I tend to wet some pH paper and stick it in the air in the pot to see if there's anything 'gassy' happening in there.

If there's enough Chlorine or HCl coming off, it'll go pink/red.

[Edited on 16-10-2015 by aga]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

It was a guess.

Acetic acid.

Copper.

Might make copper acetate !

|

|

|

Bezaleel

Hazard to Others

Posts: 444

Registered: 28-2-2009

Member Is Offline

Mood: transitional

|

|

Great work, kadriver, thanks for making and sharing this very well done video! And writing in text that tells what you do, is a really good idea -

thanks.

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

There will always be some small amount of chlorine in solution and so the liquid should smell of it, like aga described, a strong

bleach-like odour. This is fine. What we're trying to avoid is the profuse bubbling off of chlorine, which seems to not occur at pH 4.5, so that's

good.

|

|

|

dlog

Harmless

Posts: 9

Registered: 9-9-2016

Member Is Offline

Mood: No Mood

|

|

Well

This is related to the topic. Last post was in 2015 but I would like to know if somebody here did some test within this collected info around web.

1#

Search in libgen.io for "gold leaching" or id:1553889

The below article is avaliable but they use THF

GOLD LEACHING IN ORGANIC SOLVENTS: SIMPLE AND MILDE REACTION CONDITIONS FOR FAST GOLD DISSOLUTION

2# (This is for palladium but I believe it works for gold)

http://web.cim.org/com2015/conference/Poster_Session.pdf

POSTER TITLE: A highly effective system for palladium dissolution under mild conditions (PAPER ID:

9200)

In the present work, a new method has been introduced for the dissolution of palladium under very mild

conditions. Palladium was quickly dissolved in some particular organic solvents including acetonitrile, ethyl

acetate or acetic acid containing low concentrations of hydrochloric acid, hydrogen peroxide and CaCl2. Among

these three organic solvents, acetic acid showed the highest rate of palladium dissolution. The rate of 1200 gm-

2h-1 was measured at room temperature in acetic acid containing 0.5 M HCl, 0.2 M H2O2 and 0.2 M CaCl2 . The

dissolution rate significantly increased to 4500 g m-2 h-1 by raising the temperature up to 60 oC. The dissolved

palladium was precipitated out using Zn powder as a reducing agent. This new leaching method is highly promising

to find industrial applications for recovery of palladium from both primary and secondary sources like,

PGM ores, spent catalysts, copper anode slime and jewelry scraps.

3# (Very recente, from 2016, october)

http://artsandscience.usask.ca/chemistry/news/article.php?ar...

In the second process, a comprehensive set of water-miscible organic solvents including small amounts of HCl, CaCl2

and some oxidizing reagents were used as new leaching systems for gold. Among all studied solvents, acetic acid provided

the highest gold dissolution rates reported to date. Along with an unmatched gold dissolution rate, this new leaching

system was also highly selective for gold over base metals such that in the case of electronic scraps, more than 99% of gold

was extracted from printed circuit boards (PCBs) in less than 20 seconds (which is the fastest known gold recycling process

from e-waste ever reported) while less than 1.5% of nickel, 0.3% of copper, and 0.05% of all of the other base and heavy metals

were leached during the same contact time. This new discovery promises to replace highly hazardous chemicals commonly used for

gold recovery and opens new opportunities into the field of gold extraction for future studies.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

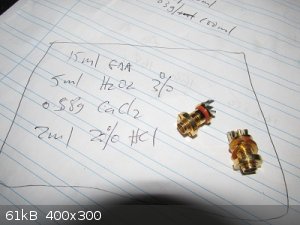

A quick knock-up of their solution doesn't seem to do anything to gold.

What i mixed up, plus the gold-plated computery bits.

After 5 minutes there appears to be no attack on the gold.

The parts have been put back into the solution to see if anything happens overnight.

|

|

|

dlog

Harmless

Posts: 9

Registered: 9-9-2016

Member Is Offline

Mood: No Mood

|

|

Hello aga,

I have tried many combinations here without sucess

But in the 3# we got some good and new information: Acetic acid, CaCl2, HCL + oxidant (Guessing H2O2) maybe another chemical....

For me until now, no sucess.

|

|

|

| Pages:

1

..

6

7

8

9 |