Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

sebacic acid

I recently synthesized sebacic acid (decandioic acid) as a by-product of a synthesis for 2-octanol. I used a 1/6 scale batch based on the synthesis

presented in Vasishtha's article in the "Journal of American Oil Chemists Society," 1990 (see References thread). My target was the 2-octanol and I

only recovered the sebacic acid as it was there for the taking.

25g of USP castor oil was charged to my newly fabricated 500 ml copper RBF along with 75ml of water, 66.7g of mineral oil (bp > 310°C), 20g of

NaOH, and 0.25g of red lead (catalyst). This was pyrolized to yield a distillate of 2-octanol. The sebacic acid was recovered from the pot residue.

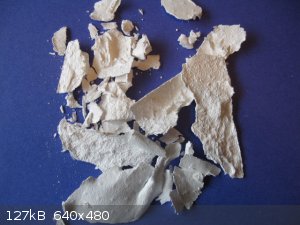

The acid yield was 3.8g of off-color (light tan) powder, for a %yield of 44.2%. This impure product had a mp of 127°C vs the 134.5°C literature

value. As I have no immediate need for this product I will store it as impure acid.

The 2-octanol containing distillate was dried over K2CO3 to a translucent yellow liquid weighing 9.9g (expected yield 6.4g). I will not purify this

further until I can add 2 more batches to it. I will report on this when the purification is complete.

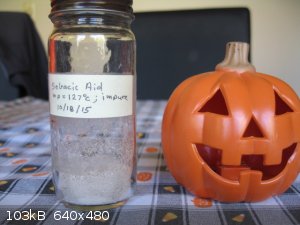

The first photo below shows the 3 products of the pyrolysis (max temp 317°C): (1) the sebacic acid on the left, (2) the distillate in the separator

funnel, and the degraded mineral oil diluent added to kitty litter in the jar. The second picture shows the impure sebacic acid.

[Edited on 19-10-2015 by Magpie]

[Edited on 19-10-2015 by Magpie]

[Edited on 19-10-2015 by Magpie]

[Edited on 19-10-2015 by Magpie]

[Edited on 19-10-2015 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Hawkguy

Hazard to Others

Posts: 326

Registered: 10-10-2014

Location: British Columbia (Canada eh!)

Member Is Offline

Mood: Body is Ready

|

|

Have you thought of making Dioctyl sebacate?

|

|

|

UC235

National Hazard

Posts: 565

Registered: 28-12-2014

Member Is Offline

Mood: No Mood

|

|

Interesting, as usual uncatalyzed pyrolysis of castor oil gives undecylenic acid and heptanal.

|

|

|

Oscilllator

National Hazard

Posts: 659

Registered: 8-10-2012

Location: The aqueous layer

Member Is Offline

Mood: No Mood

|

|

Interesting post Magpie. I have been wondering for some time how one could easily make some longer chain alcohols for the purposes of making esters,

and this fits the bill nicely.

I have three questions:

-Did you use the copper flask just because it was new, or for another reason?

-What purpose did the mineral oil serve? Was it just there to raise the temperature of the reaction mixture or did it serve a different purpose?

-How did you remove the lead from the flask? Obviously you couldn't use nitric acid, but Hydochloric acid and sulfuric acid wouldn't really work

either because of the solubility of the respective lead compounds

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

It is specified in the Org Syn procedure (methyl-n-hexylcarbinol). The JAOCS procedure uses a steel vessel. NaOH at pyrolysis temperatures would

destroy glass.

Quote: Originally posted by Oscilllator  |

-What purpose did the mineral oil serve? Was it just there to raise the temperature of the reaction mixture or did it serve a different purpose?

|

It is a high temperature, inert, diluent.

Quote: Originally posted by Oscilllator  |

-How did you remove the lead from the flask? Obviously you couldn't use nitric acid, but Hydochloric acid and sulfuric acid wouldn't really work

either because of the solubility of the respective lead compounds

|

I'm not sure of the lead's fate, except it is not in the distillate.

Hawkguy: No, hadn't thought of making anything with this. If you search for sebacic acid (on this forum) you will find a link to a very interesting

use in the medical field: making a polymer with glycerol. This is a glue for heart surgery, etc.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Boffis

International Hazard

Posts: 1838

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Nice work Magpie, its nice you see some actual practical chemistry reported. I had seen a reference to sebecic acid coming from caster oil but I had

presumed that the process was simply the hydrolysis of a glycerol ester. Do other unsaturated glycerol esters react similarly? You wouldn't get the C8

alcohol because there is no OH group on the chain (so you would get a hydrocarbon?) but you should still get the sebecic acid or similar from the

residue. Perhaps azelaic acid from olive oil.

I looked at trying to prepare cyclononone once by thermal degradation of barium or calcium sebecate but apparently this doesn't work with >C8 acid

according to a reference I found.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I really haven't looked into the chemistry beyond what is in the JAOCS article as found here: http://www.sciencemadness.org/talk/viewthread.php?tid=62326&...

I saponified the castor oil first. Then just dumped the products in the RBF along with the other ingredients which included more NaOH.

I don't know what all is in that distillate. I just hope I can isolate some pure 2-octanol.

[Edited on 20-10-2015 by Magpie]

[Edited on 20-10-2015 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I finished two more batches pyrolizing castor oil. The sebacic acid for the 2nd batch was not recovered. That for the 3rd batch was recovered in

98.0% yield and in high purity - it was absolutely white. The mp was 129.5°C. Wiki states the mp as 131-134.5°C. I am wondering if there is some

polymorphism here as I cannot believe that it is not pure. Shown below is the aqueous slurry of the acid before and after removal of the mineral oil.

Also shown is the solid acid after removal from the filter paper. This last batch was made with Up & Up (Target) mineral oil "as received."

I will be making two more batches. One will use Up & Up and the other will use paraffin in place of mineral oil.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Pumukli

National Hazard

Posts: 686

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

What happened to the second batch? Did something go wrong and you sent it down the drain? :-)

I enjoy your synths, Magpie! Keep up!

|

|

|

byko3y

National Hazard

Posts: 721

Registered: 16-3-2015

Member Is Offline

Mood: dooM

|

|

It's not possible ot obtain something close to quantitative yield of sebacic acid using this method. I'd say 80% is the highest yield you could ever

achive.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by Pumukli  | What happened to the second batch? Did something go wrong and you sent it down the drain? :-)

I enjoy your synths, Magpie! Keep up! |

Thanks, Pumukli. I let the residue cool off too much before adding hot water so I did not get much acid and it was highly contaminated. I could have

reheated and recovered it but did not want to bother. It went out as a gel with the kitty litter.

Quote: Originally posted by byko3y  | | It's not possible ot obtain something close to quantitative yield of sebacic acid using this method. I'd say 80% is the highest yield you could ever

achive. |

I don't disagree. I just calculated the yield using the weight of the acid.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

byko3y

National Hazard

Posts: 721

Registered: 16-3-2015

Member Is Offline

Mood: dooM

|

|

Friendly speaking, i don't think lead oxides are needed at all. Most likely indian piece of shits just needed to write another article. My advise: any

time you see an article from india, iran, pakistan, korea - just throw it away. Well, you can get some usefull links from theirs works - that's pretty

much all.

US patent 2674608

| Quote: | A mixture of:

385 grams caustic soda

139 grams tri-cresol (mixture of isomers)

110 grams Water

500 grams castor oil

is subjected to mechanical agitation and gradually heated to 250°C. At about 135°C, water and some octanone-2 begin to distill of. These compounds

are condensed and recycled into the reaction apparatus. As the temperature rises, the rate of distillation of the water and the organic compounds

distill increases. At about 210°C. a discharge of hydrogen is observed. Heating is continued until a temperature of 250°C. is reached and this

temperature is then maintained over a period of 2 hours, all the while continuing to reflux the condensed volatile compounds into the reactor. After

the reaction has been completed, the recycling of the condensates is stopped and these condensates are recovered separately. The distillate comprises

a lower aqueous layer and an upper layer of organic products whie chiefly contain octanol-2. The organic layer is rectified, and 136 grams of a

mixture containing 95% octano1-2 and octanone-2 is recovered.

The reaction mass is dissolved in about liters water. The alkaline solution is acidified with diluted sulfuric acid until a pH of about 2 is obtained,

releasing the organic acids and the phenols. The mixture is brought to a boil, whereupon the sebacic acid becomes dissolved in water and the phenols

and other organic acids form a supernatant oily layer. The hot aqueous solution is subjected to a settling step, bleached with activated carbon and

filtered hot. On cooling, the sebacic acid crystallizes from the solution. The crystals are drained, washed with water and dried.

208 grams of 99% pure sebacic acid are obtained in this way. |

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by byko3y  | Friendly speaking, i don't think lead oxides are needed at all. Most likely indian piece of shits just needed to write another article. My advise: any

time you see an article from india, iran, pakistan, korea - just throw it away. Well, you can get some usefull links from theirs works - that's pretty

much all.

|

I appreciate you speaking frankly here. I am not without sympathy on this. It seems that many modern articles and patents are of dubious value,

regardless of source.

Organic Syntheses procedures generally do work. They were produced to provide the US with chemicals that were no longer available from

Germany during WWII. They were not published because some grad students needed to "publish or perish." The Org Syn procedure for

methyl-n-hexylcarbinol (2-octanol) does not use an adjunct such as lead oxide.

The procedure I'm using is a combination of the Indian and Org Syn procedures. It is producing sebacic acid. Time will tell if I get any

decent yield of 2-octanol.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I finished the final runs, ie, batches #4 and #5. These were both made with Up & Up mineral oil as it was working well and I was concerned that

the use of paraffin wax might cause problems.

4th batch: %yield =75.6%; mp = 129-131°C

5th batch: %yield = 93.0%; mp = 128-130°C

I think that an average yield of 84.3% is more meaningful as the feed for these 2 batches was split from a common batch of saponified castor oil.

Batch #1 was so impure I threw it out. Batch#2 was not recovered. The combined yield for batches #3, #4, and #5 is 22.9g for a combined % yield of

88.8%. Here again splitting a common batch of saponified castor oil 3 ways likely has skewed the yield of batch #3 to the high side.

Here is a crude video of the precipitation of the batch #4 sebacic acid:

https://youtu.be/VD2fJ7Gtm5Q

https://youtu.be/SXyLJWEmF3o

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|