deadpool

Harmless

Posts: 21

Registered: 13-3-2014

Member Is Offline

Mood: No Mood

|

|

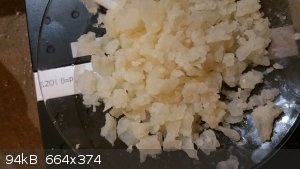

Binder issue =(

Hello guys & pyrotechnic gods (or goddess). I have a binder issue. I've read a few post and thought I would give it a try, typically I ended up

wasting a lot of product and created a sticky mess. My method was to use polybutene and methylricinoleate (also tried small amounts of oil). I

created the methylricinoleate via esterification with methanol and caster oil. My product was a liquid, but once cooled turned into a sold mass. I

don't know anything about this product and thought perhaps I made a mistake during the esterification process. I did use sodium hydroxide as the

catalyst, which may have been a mistake. Can anyone confirm if this is the right product? Also am I also correct to assume that total inert

materials shouldn't exceed 10% by weight? I have extreme difficulty getting 10% plasticizer/binder to mix that well.

|

|

|

DubaiAmateurRocketry

National Hazard

Posts: 841

Registered: 10-5-2013

Location: LA, CA, USA

Member Is Offline

Mood: In research

|

|

Umm, what is the majority of that mass?

|

|

|

deadpool

Harmless

Posts: 21

Registered: 13-3-2014

Member Is Offline

Mood: No Mood

|

|

This was the product of the caster oil esterification, guess I should have been more clear on that sorry.

|

|

|

deadpool

Harmless

Posts: 21

Registered: 13-3-2014

Member Is Offline

Mood: No Mood

|

|

answering my own question, comments are welcome!

It looks to me like the sodium hydroxide turned the castor oil into a fat  yup..

just googling showed me methyl ricinoleate is a liquid... dang it. Should have I just used an acid for the esterification? Guess I'll try it again. yup..

just googling showed me methyl ricinoleate is a liquid... dang it. Should have I just used an acid for the esterification? Guess I'll try it again.

|

|

|

Deathunter88

National Hazard

Posts: 508

Registered: 20-2-2015

Location: Beijing, China

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by deadpool  | It looks to me like the sodium hydroxide turned the castor oil into a fat  yup..

just googling showed me methyl ricinoleate is a liquid... dang it. Should have I just used an acid for the esterification? Guess I'll try it again. yup..

just googling showed me methyl ricinoleate is a liquid... dang it. Should have I just used an acid for the esterification? Guess I'll try it again.

|

You used sodium hydroxide for an esterification?! No wonder you got such a weird product. Try the same procedure again but this time try using

concentrated sulfuric acid instead of the sodium hydroxide.

|

|

|

NitreRat

Harmless

Posts: 45

Registered: 22-1-2015

Location: Cyberspace

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Deathunter88  | Quote: Originally posted by deadpool  | It looks to me like the sodium hydroxide turned the castor oil into a fat  yup..

just googling showed me methyl ricinoleate is a liquid... dang it. Should have I just used an acid for the esterification? Guess I'll try it again. yup..

just googling showed me methyl ricinoleate is a liquid... dang it. Should have I just used an acid for the esterification? Guess I'll try it again.

|

You used sodium hydroxide for an esterification?! No wonder you got such a weird product. Try the same procedure again but this time try using

concentrated sulfuric acid instead of the sodium hydroxide. |

Or better still, use sodium methoxide. Maybe even, the more easily made, magnesium methoxide, but I'm not sure about that one.

|

|

|

Microtek

National Hazard

Posts: 830

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

What you have is likely the sodium soap of ricinoleic acid.

I think you should go back one more step; castor oil is a triglyceride, so you could either make a trans-esterification, or you could liberate the

ricinoleic acid first (eg. by hydrolysis with hydroxide). Then after purifying the fatty acid you can do the esterification with methanol and sulfuric

acid.

[Edited on 8-12-2015 by Microtek]

|

|

|

deadpool

Harmless

Posts: 21

Registered: 13-3-2014

Member Is Offline

Mood: No Mood

|

|

Yea i was suppose to mix the methanol and sodium hydroxide to form sodium methoxide first, and I goobered on that part. Thanks guys for the help!

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

When I made some recently I used these ratios.

Mix 50ml castor oil 20ml methanol 0.3 grm potassium hydroxide together , stir and reflux at 100°c for 3 hours use a vertical condenser to stop

methanol loss, after 3 hours dilute with h2o and seperate oil layer, dont over agitate oil and water mix or it will take days to seperate because it

goes into an emulsion with the water.

Nux.

[Edited on 9-12-2015 by nux vomica]

|

|

|

deadpool

Harmless

Posts: 21

Registered: 13-3-2014

Member Is Offline

Mood: No Mood

|

|

More questions (feed my brain)

Hello again,

I was wanting some clarification on the hydrolysis reaction that taking place (this laborious process isn't going to be use so don't flame me, I just

want to learn).My current understanding is:

Castor oil is a triglyceride that is mainly comprised of ricinoleic acid. When water is added it the hydroxide anions will attack the triglyceride

and break it down (saccharification?) to 3 x ricinoleic acid molecules.

My questions are: Is sodium/potassium hydroxide required or is it just a catalyst? If it is, how do you prevent the soapy salt forming? Lets assume

that I wanted a high quality product and used the method provided by Microtek. From what I understand from this process I should mix castor oil &

water (perhaps with hydroxide salt) and setup for fractional distillation to yield pure ricinoleic acid in receiving glass.

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

The hydroxide is the catalyst, and by using only a tiny amount and keeping the temp fairly low 20-25c and you should be able to avoid the

saponification of the oil. I'm not sure about distilling the oil though. In my experience just washing the oil with a little water to remove methanol

any excess catalyst and glycerol formed is sufficient. By putting the product into a measuring cylinder and letting water run through this works for

me while preventing too much loss if an emulsion formed with the water. Further methanol can just be warmed off and the oil dried over a dessicant if

needed. The end result was the nice clear Kind of thin oil suitable for plastics.

|

|

|