| Pages:

1

..

52

53

54

55

56

..

60 |

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

Can't access the references page of this book, but here's some info for you. You'll likely have to use an excess of carbon, with carbon monoxide as a

product instead of carbon dioxide.

Also, in coal or charcoal there's going to be some hydrogen in there, which likely means phosphine production.

|

|

|

clearly_not_atara

International Hazard

Posts: 2722

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

A eutectic of tin and zinc phosphates forms a glass with softening temperature approximately 440 C. These are much cheaper than barium or silver as

was discussed before. However there is still the unfortunate possibility that the melt will react with Pyrex :p

http://repository.kulib.kyoto-u.ac.jp/dspace/bitstream/2433/...

As WGTR notes, you want to use plenty of carbon. CO is the waste product.

|

|

|

BluePlanet1

Harmless

Posts: 41

Registered: 30-1-2016

Member Is Offline

Mood: No Mood

|

|

Thanks everyone for the responses. I doubled the weight of carbon but still got a few small issues to figure out.

Like packing the reagant into the retort. I have to "drop pack" it in, then turn it sideways and it still spills out too close to the neck.

Although I could just use less powder I'm trying to pack it as much as possible. So there's less air in the retort and also to test

how easy it is to clean out large loads.

What I'm doing is lightly plugging the retort with tissue before screwing the distiller on.

My hope is that the heat will burn out the tissue to flakes BEFORE CO gas starts spewing out.

Otherwise if pressure builds up too quick it could be dangerous.

So right now I need to run a few dry fires just to time how lightly I need to pack the tissue so the seal breaks before the reaction begins.

It's a small detail but I need to get this right so hopefully by the weekend I"ll be ready. :-)

[Edited on 24-3-2017 by BluePlanet1]

|

|

|

clearly_not_atara

International Hazard

Posts: 2722

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Interesting. I hope your phosphorus synthesis works out.

This may sound like a bit of an odd request, but if you happen to have some tin and iodine handy, I'm deadly curious to see what would happen if the

phosphorus stream were condensed in the presence of SnI2. It might have to be done under anhydrous condition or in a hot solvent to prevent

disproportionation (SnI2 >> Sn + SnI4), but under the right conditions, condensing phosphorus vapor in the presence of SnI2 produces black

phosphorus -- and it would be nothing short of incredible if this could be done with a freshly synthesized stream of phosphorus. If you do produce

black phosphorus, it would be worth tens of dollars per gram, AFAIK.

A bit of a crazy idea -- no need to try it, right? :p

|

|

|

yobbo II

National Hazard

Posts: 719

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

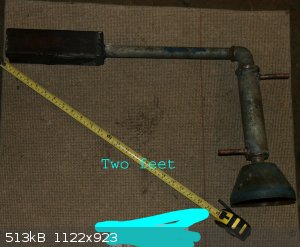

Finished making retort. Filled slot with fireclay. Had to force the two halves together using a bottle jack and two walls!

All looked well. Heated very slowly for to cure the firclay.

Let cool and tested the retort for air tightness by submerging in water and blowing into outlet. Air bubbles came out the joint. Not too many but not

100% air tight. Would possible do the job but I am not going to run with it.

RETORT = BUMMER.

Far too much bother and trouble and leaks air.

I will simply dismantle, weld together and go with that. It would be far handier to weld and cut each time I need to reuse the retort that to be

messing with the fire clay, bottle jacks and heating to cure etc etc.

edit

Battered (and battered and battered) the retort to get the lid off. I ended up cutting the 'lid' off.

Rewelded and am nearly ready to go. I have to weld some holes that are on the anti suck back funnel.

I am using a Magpie condensor (steel with 80 degree water).

Hope all goes well. I am looking forward to selling large quantities of black P

Yob

[Edited on 3-4-2017 by yobbo II]

|

|

|

Elemental Phosphorus

Hazard to Others

Posts: 184

Registered: 11-11-2016

Location: Is everything

Member Is Offline

Mood: No Mood

|

|

I just realized that iron phosphide may make an excellent precursor for the production of phosphorus, since it is not controlled, and I found a

supplier for it for about $5/kg plus shipping. According to Wikipedia, it is soluble in nitric acid, so maybe a solution of it could be made, and a

stochiometric amount of chlorine bubbled in to oxidize Fe3P2 to 2FeCl3 + 2P (if that reaction works). Also, it could be burned and the resulting P2O5

reduced with aluminum powder

|

|

|

j_sum1

Administrator

Posts: 6251

Registered: 4-10-2014

Location: Unmoved

Member Is Offline

Mood: Organised

|

|

Seems like an interesting idea. Per gram it seems rather cheap.

|

|

|

Si Da Sci Guy

Harmless

Posts: 7

Registered: 23-4-2017

Member Is Offline

Mood: No Mood

|

|

great idea Elemental Phosphorus, not sure what will happen with the nitrate ion ( from the HNO3 ), but if it works you'll be a hero. Just remember...

SAFETY FIRST

|

|

|

Elemental Phosphorus

Hazard to Others

Posts: 184

Registered: 11-11-2016

Location: Is everything

Member Is Offline

Mood: No Mood

|

|

Yeah, I was worried about the nitric acid oxidizing the phosphorus to the pentoxide, and dehydration of the remaining acid to N2O5. An ideal solvent

for the reaction would maybe be chloroform, unfortunately wikipedia lists iron phosphide as soluble in HF, nitric acid and aqua regia. Chlorination of

a molten bath of phosphide is out of the question, but maybe the iron phosphide can be converted to an easier-to-work with zinc phosphide by zinc

metal.

|

|

|

Si Da Sci Guy

Harmless

Posts: 7

Registered: 23-4-2017

Member Is Offline

Mood: No Mood

|

|

I was thinking perhaps I could use urea phosphate, dissolve it in water and then chemically destroy the urea, then reduce the phosphate with carbon to

phosphorous.

Any thoughts on that guys?

|

|

|

Elemental Phosphorus

Hazard to Others

Posts: 184

Registered: 11-11-2016

Location: Is everything

Member Is Offline

Mood: No Mood

|

|

That should work, but only at high temperatures. (above the boiling point of water) Phosphate is very resistant to reduction, and this reaction would

likely take a few hundred degrees celsius to proceed.

|

|

|

Aqua-regia

Hazard to Others

Posts: 126

Registered: 18-12-2006

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Elemental Phosphorus  | | I just realized that iron phosphide may make an excellent precursor for the production of phosphorus, since it is not controlled, and I found a

supplier for it for about $5/kg plus shipping. According to Wikipedia, it is soluble in nitric acid, so maybe a solution of it could be made, and a

stochiometric amount of chlorine bubbled in to oxidize Fe3P2 to 2FeCl3 + 2P (if that reaction works). Also, it could be burned and the resulting P2O5

reduced with aluminum powder |

Do you have some reference abouth this? Iam sceptic that P will unattacked by chlorine.

|

|

|

clearly_not_atara

International Hazard

Posts: 2722

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Fe3P2 may not be a very good precursor for phosphorus, but it could nonetheless be an excellent precursor for phosphorus halides, and therefore also

for triphenylphosphine.

IMO triphenylphosphine is the real prize -- it opens the door to a lot of safe replacements for otherwise dangerous or inconvenient reactions, notably

the Appel and Wittig reactions, as well as hydrogenations utilizing Pd(Ph3P)4 and Cu(Ph3P)6H.

It might however be possible to use FeCl3 rather than chlorine to digest Fe3P2:

6FeCl3 + Fe3P2 >> 9 FeCl2 + 1/2 P4

This has a higher chance of producing elemental phosphorus, since I don't think P will reduce iron trichloride, and the comproportionation of iron

chlorides is favorable IIRC.

|

|

|

Elemental Phosphorus

Hazard to Others

Posts: 184

Registered: 11-11-2016

Location: Is everything

Member Is Offline

Mood: No Mood

|

|

I am skeptical as well, but if the amount of chlorine was controlled, and only enough to produce FeCl2 was added, it might work. Also, the iron

phosphide could be reduced to zinc phosphide with zinc metal, and then the zinc phosphide could be chlorinated to ZnCl2, or alternatively, oxidized to

ZnO and phosphorus with careful control of the oxygen.

|

|

|

Aqua-regia

Hazard to Others

Posts: 126

Registered: 18-12-2006

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Elemental Phosphorus  | | I am skeptical as well, but if the amount of chlorine was controlled, and only enough to produce FeCl2 was added, it might work. Also, the iron

phosphide could be reduced to zinc phosphide with zinc metal, and then the zinc phosphide could be chlorinated to ZnCl2, or alternatively, oxidized to

ZnO and phosphorus with careful control of the oxygen. |

This theory is a joke. How do you think if even some phosphorus relased these sitting in the bottom of flask ,and waiting for other phosphorus

molecule, while chlorine / oxygen is very polite and reacting only with zinc and giving a shit for free phosphorus? Science and fantasy are

different things.

[Edited on 26-4-2017 by Aqua-regia]

|

|

|

Elemental Phosphorus

Hazard to Others

Posts: 184

Registered: 11-11-2016

Location: Is everything

Member Is Offline

Mood: No Mood

|

|

But, phosphorus halides are very reactive, whereas metal chlorides are certainly not. Think about this:

Zinc reacts in HCl to give hydrogen and ZnCl2, since it is a good reducing agent.

Phosphorus does not react in HCl, as it is not as powerful of a reducing agent.

Phosphorus halides hydrolyze, ZnCl2 does not. Zinc's electronegativity is 1.65, whereas phosphorus's electronegativity is 2.19. I think it is

ludicrous to suggest that chlorine would react with something 1 away in electronegativity rather than 1.5 away. Come on, do you think you could reduce

ZnCl2 with phosphorus?

I guess we'll see when I finally get my hands on some phosphides then...

|

|

|

clearly_not_atara

International Hazard

Posts: 2722

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

It is possible that phosphorus will react first simply because it encounters the chlorine molecules first:

http://en.wikipedia.org/wiki/Thermodynamic_versus_kinetic_re...

The reaction of metal phosphides with chlorine is kinetic. So if stoichiometric chlorine is used the result may be that half of the iron phosphide is

converted to iron and phosphorus halides while the other half remains unreacted.

However, phosphorus halides are, of course, valuable in and of themselves, and it may be possible to reduce them to the pure element.

It may be possible to reduce PCl3 with a metal amalgam or possibly molten tin.

[Edited on 27-4-2017 by clearly_not_atara]

|

|

|

Aqua-regia

Hazard to Others

Posts: 126

Registered: 18-12-2006

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by clearly_not_atara  | It is possible that phosphorus will react first simply because it encounters the chlorine molecules first:

The reaction of metal phosphides with chlorine is kinetic. So if stoichiometric chlorine is used the result may be that half of the iron phosphide is

converted to iron and phosphorus halides while the other half remains unreacted.

[Edited on 27-4-2017 by clearly_not_atara] |

This is the point.

You can chlorinating red phosphorus in CCl4 suspension to PCl5. The reaction is very exothermic even in -20 degrees. The white one is more reactive.

If we examine the phosphide properties i would suggestion the termal decomposition of PH3. This is not enough stable molecule. Generate PH3 stream,

destroy the evolving diphosphine with HCL and lead the gas into hot glas reactor tube. I fulfilled this in microscale a couple year before. This

is workable. Nasty work of course, cause PH3 is very poisonous and extrem flammable. This is definatelly not for beginner!

|

|

|

Elemental Phosphorus

Hazard to Others

Posts: 184

Registered: 11-11-2016

Location: Is everything

Member Is Offline

Mood: No Mood

|

|

I am inclined to simply chlorinate all the way to the phosphorus chloride and metal chloride and then distill off the phosphorus chloride, since the

main reason I wanted phosphorus was to generate its halides, although I think the halide could be reduced with magnesium metal.

Edit: The chloride could be refluxed over Mg metal turnings or powder

[Edited on 27-4-2017 by Elemental Phosphorus]

|

|

|

Aqua-regia

Hazard to Others

Posts: 126

Registered: 18-12-2006

Member Is Offline

Mood: No Mood

|

|

My suggestion: do it. The name of process experimental chemistry

|

|

|

BluePlanet1

Harmless

Posts: 41

Registered: 30-1-2016

Member Is Offline

Mood: No Mood

|

|

Ok folks, I'm back!

FIRST LARGE SCALE CARBON-PHOSPHATE TEST FIRE WAS DONE LAST NIGHT.

I may post pictures later but things didn't go as planned and I still have tweaking to do.

I packed the retort with coal, phosphate, silica and then wrapped thread around a tiny cotton ball (like a tampon) to plug the end of the retort. This

way I could pack the sand base layer in (that seals the threads)... pull the thread through the distiller... and after the pipes are screwed / sand is

packed, I turned the whole furnace sideways, mounted the exhaust cap, pulled the thread and cotton ball out to unblock the outlet then fired it off.

Within 1-2 minutes gas started coming out the distiller. Everything looking great.

After 3-4 minutes the furnace gets yellow.... then CO2 gas starts coming out with a good degree of force.

After 5 minutes it got bright yellow-white... and now CO2 is spewing out of the distiller so damn fast I start getting nervous.

After 5 minutes the gas was coming out at such an unexpectedly high volume, with so much unbelievable force and speed that my hands start shaking

uncontrollably. As I thought "I really should have built that torch mount".

Around 6-7 minutes the gas expulsion was now a nonstop torrent. The bubbling sound from the distiller stopped. The distiller was about 1/2" under the

water. I looked to see what happened and the gas was coming out so fast that the surface of the water couldn't hold it back anymore. It's now gurgling

like a drain. As this torrent of super heated CO2 starts launching water out of the collector and now the distiller was barely submerged about 1/4".

Around 8+ minutes the CO2 would not let down at all. And this is when I noticed trademark phosphine explosions. But these explosions were no joke.

Like 5-10 explosions every second in different angles dancing around the surface of the water which blew more water out of the collector. So now my

right hand is shaking real bad. I grab water to level off the collector and as I'm pouring the water in the rapid fire phosphine explosions ERUPT INTO

A JET OF FIRE AND SMOKE. A stream of fire about 8-12" high is now pouring from the surface of the water.

As I'm watching I think, "no way this is phosphine." This was pure P4 vapor burning off like one of those bombed oil wells in Iraq. Producing tons of

white smoke.

I hesitated about 30 seconds trying to figure out what to do with my shaking hand vs the reaction. I looked in the collector thinking "is ANY P4

condensing", I look. It's milky white. I think "great", looks like it's.... kinda working. Except so much damn phosphorus is burning off straight from

the water I realize this dynamic can't be changed (mid reaction). And that most of the P4 would burn off and not condense.

Then right as I'm about to lower the propane gas, my hand shook so bad it knocked the furnace off it's magnet mount and out came an explosion of black

coal dust right out of the distiller. The milky white water turned pure black. I got mad as hell and shut it down.

As I pulled the collector from the distiller the fire on the surface of the water isolated itself and wouldn't go out. I grabbed the sides of the

glass and noticed the water was hot as hell. It was fairly cold when I poured it in.

So I ran and grabbed ice, threw it in the water, stirred, then yay the fire went out.

With the coal reaction using an insulated furnace and propane-air.... the CO2 gas comes out so hot so fast at such high volume it heats the water up

in the collector unbelievably fast.

That's the first thing I learned. I did NOT need an icebath for the Al reaction ever. But the CO2 reaction absolutely needs one.

Second thing I learned is where the Al reaction often condenses P4 in the distiller or clogs it.... the carbon reaction wants to do the opposite. It

throws out so much CO2 so fast that unless you have the distiller submerged fairly deep in really cold water.... the P4 vapor barely condenses and is

carried straight out the distiller, hits the surface of the water and burns in a stream of fire.

I saved the collector water but the bottom is about 1/2" of coal dust. And I know P4 is in there somewhere because everytime I open it the water

smokes and stinks like it. Just not sure how to separate it yet.

THE GOOD NEWS I'D SAY IS THE FOLLOWING:

1) The coal redux clearly works at air-propane temperatures.

2) Perlite dust as a packing agent also works GREAT. The threads on my pipes didn't even match (there were small air gaps) but it still stopped leaks

100%.

3) The perlite packing agent does melt a bit on the surface. But all I did was fracture it with a screw driver and was quickly able to dislodge the

retort.

4) The brass adapter and distiller did not melt at all.

5) There was virtually no corrosion on any of the threads or pipes.

6) The part of the distiller that comes out the furnace did corrode a bit. And so did the stainless steel retort in the forge but after a quick

wirebrush I saw no oxide or flakes peel off. Just a darker color change.

7) The reaction didn't complete but the "slag" inside the retort wasn't a slag at all. It was all black powder with lumps here and there that broke

down and poured out quick.

In regards to temperature.

I got these #s from an accurate source but am citing them off the top of my head.

The carbothermal redux kicks off approximately 1080C-1100C.

Around 1250C the highest potential yield is limited to between 50-60%.

The full conversion range for a 99% yield is pretty high at roughly 1400C.

I'm still not sure how hot my forge is getting but I'm assuming it's mid range around 1250C. Maybe higher maybe lower.

According to the data I think a good yield would be 50%. And I can try to push the temp up higher in various ways but I'm thinking it may be smart to

get this reaction nailed down right first. Build my torch mount. Longer distiller. Ice bath. Figure out my current yield (on next fire). Then maybe,

slowly reverse my way back to adding a certain % of Al.

This could reduce the max yield temp. And also reduce the insane gas output. It's just a question of how much carbon I need to stop Al from locking up

the slag. And I haven't even experimented with adding NaCL like Roger did.

That's about it for now. Just wanted the forum to know I did my first large scale (50gm) carbon test fire. And though it failed a lot of P4 burned off

that I will collect next time. I think yields will be pretty decent and much preferable to pure Al due to how quick everything can be disassembled and

refired.... that alone is a huge step forward imo.

I'll be back soon & hopefully on camera next time. :-)

|

|

|

clearly_not_atara

International Hazard

Posts: 2722

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Ow, damn, glad you're ok... It requires some bravery to do this.

Maybe we can calculate the heat that will be produced and corresponding volume of water required to quench it... Mighr be pretty high.

|

|

|

jgourlay

Hazard to Others

Posts: 249

Registered: 9-7-2008

Member Is Offline

Mood: No Mood

|

|

Blueplanet: that's an old school successful disaster! Awesome!

|

|

|

yobbo II

National Hazard

Posts: 719

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

If you had more controlled heating would that help. If you held the temperature at say 950C for some time before going on upwards would that help with

the gas output?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Very interesting experiment.

Where's all the oxygen for the CO2 coming from - the phosphate? Coal contains a lot of hydrogen and is probably responsible for all that phosphine

(PH3).

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

| Pages:

1

..

52

53

54

55

56

..

60 |