| Pages:

1

2 |

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

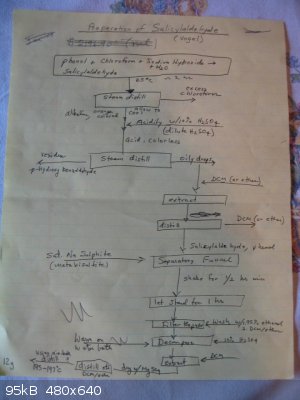

Preparation of Salicylaldehyde

a lab report

A. Introduction

Salicylaldehyde (SA) can be prepared using a Reimer-Tiemann reaction, ie:

Attachment: Reimer-Tiemann.doc (26kB)

This file has been downloaded 833 times

reaction

This reaction proceeds through formation of a :CCl2 carbene as shown in reference 1.

I followed the procedure found in Vogel’s 3rd ed, page 703 (ref 2). The expected yield is 12g. My crude flowsheet for this preparation is shown

below:

SA preparation flowsheet

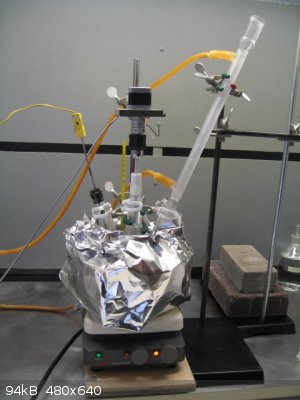

B. Apparatus

3-neck 1000 ml RBF (24/40)

overhead stirrer

west condenser (24/40)

west condenser (19/22)

60 ml p-e addition funnel

hotplate

thermocouple w/readout

2-quart waterbath (steel bowl)

distillation head (24/40)

distillation head (19/22)

vacuum adapter (19/22)

adapter (24/40 to 19/22)

100 ml RBF (19/22)

25 ml RBF (19/22)

cooling water (iced) supply

1000 ml heating mantle

100 ml heating mantle

aluminum foil

fiberglass insulation blanket

thermometer good to 200°C

steam distillation apparatus:

1. 500 ml separation funnel (steam trap)

2. 5mm x 30cm glass tube

3. 2-hole rubber stopper

4. ¼” latex rubber tubing, ~2’

5. hot plate

6. pressure cooker

7. thermometer adapter (19/22)

8. adapter (24/40 to 19/22)

9. 2ea glass plugs (24/40)

125 ml separatory funnel

250 ml separatory funnel

miscelaneous beakers

C. Reagents

28.4g phenol (aqueous, 88%)

40.5 ml chloroform

80g NaOH

water

1M H2SO4 (~500 ml)

dichloromethane (~ 85 ml)

anhydrous MgSO4

sodium bisulfite (or sodium metabisulfite)

D. Procedure

1. Reaction

The reaction apparatus was set up as shown below. The 2nd picture shows the utilities outside the hood that were required for support.

SA reaction setup

SA utilities – outside the hood

To the 1000ml RBF was added a warm solution of 80g NaOH dissolved in 80 ml of water. To that was added a solution of 28.4g of 88% phenol dissolved in

21.6 ml of water. The water bath was kept at about 65°C. 40.5 ml of chloroform was added to the 60ml p-e funnel attached to the outlet of the

condenser using a notched rubber stopper.

40.5 ml of chloroform was added to the p-e funnel. With the overhead stirrer running at 222 rpm the chloroform was added slowly over a period of ½

hour. I attempted to keep the temperature of the reactants at 65-70°C per procedure by adding boiling water to the water bath. However, the

temperature ranged from 59°C to 64°C. I didn’t turn on the hotplate as I was afraid of a possible runaway. This never happened and I never did

have to cool the bath. The mix was then heated with the water bath boiling for another hour.

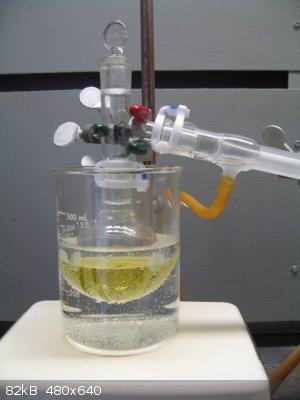

During the addition of the chloroform the reactant mix turned red and eventually turned to a dark brown, looking very much like beef gravy.

Chloroform refluxed all the while. There was foaming for a time but it was not a problem due to the generous freeboard of the 1000ml RBF. At cleanout

of the RBF a disc of tar about the size of a 50 cent piece was found at the bottom of the flask. It was soluble in alcohol and a tiny bit gave a

strong yellow coloration - dare I say à la Perkin. Pictures of the reactants at various stages are shown below:

SA reactants – later – after all chloroform added

SA reaction – during final 1 hour hold

2. Workup

The workup for this synthesis is very long, nearly discouraging me from even starting this synthesis. Garage chemist described it succintly as “a

pain.” See the flowsheet above.

a. Steam distillation to remove unused chloroform

This was performed in the 1000ml pot as shown below. I recovered no chloroform. I believe that any unused chloroform escaped from the 24/40 West

condenser (on ice-water). Vogel calls for “an efficient (double wall) reflux condenser.” I don’t have one of those. The picture below shows

the steam distillation.

Steam distillation to remove excess chloroform

b. Acidification

The pot mix was then acidified with ~250 ml of 1M H2SO4. The color of the mix lightens considerably during the acid addition.

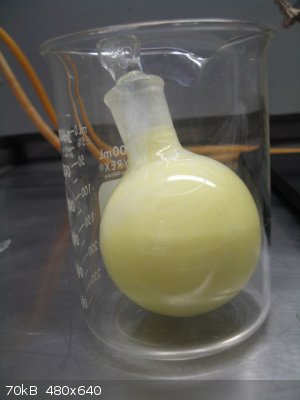

c. Steam distillation to remove the SA/unreacted phenol

A second steam distillation was now done to remove the SA and any unreacted phenol as shown below:

2nd steam distillation to remove SA/phenol

d. Extraction

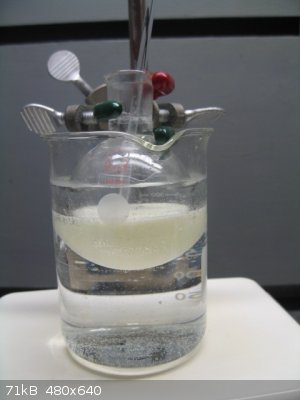

The distillate from the 2nd steam distillation was now extracted with 25ml x 25ml dichloromethane (DCM) to remove the SA/phenol from water. This is

shown below. The yellow liquid in the beaker is the first extraction, the clear liquid in the bottom of the funnel is the second extraction.

SA/phenol extraction with DCM

e. Distillation

The combined extracts are distilled to remove DCM. 45ml of good quality DCM was obtained for recycle. This is done using a water bath as shown

below:

Removal of DCM by distillation

This report is continued on the next post due to the excessive number of images.

[Edited on 30-3-2015 by Magpie]

[Edited on 30-3-2015 by Magpie]

[Edited on 31-3-2015 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

morganbw

National Hazard

Posts: 561

Registered: 23-11-2014

Member Is Offline

Mood: No Mood

|

|

Looking forward for the workup.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Continuation

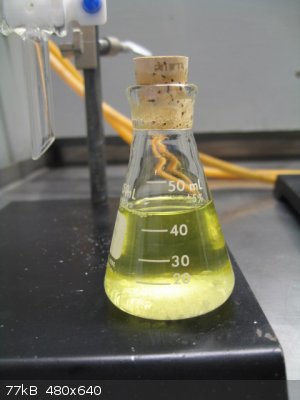

f. Sulfite adduct formation

The sulfite adduct is now formed to separate the salicylaldehyde from the excess phenol. This is done by adding 2X its volume of saturated aqueous

sodium bisulfite (I used Na metabisulfirte). Since the mix is biphasic Vogel called for this to be shaken vigorously for 1/2hr, then allowed to sit

for 1 hour. The resting product is shown below:

SA bisulfite adduct – post shaking

g. Separation of the adduct by filtration

The adduct, a pure white solid, was then separated from the water and phenol by filtration using a 7cm Buchner filter. It is shown in the picture

below:

SA adduct filtered

At one point during the filtration I did not get the filter paper properly sucked down (sealed) against the ceramic base. Consequently I lost some

product here – possibly as much as a gram. The dried adduct was weighed (17g), indicating the presence of 9.2g of SA.

h. Recovery of the salicylaldehyde

The SA is recovered by decomposition of the adduct. This is done by adding 1M H2SO4 then gently warming in a water bath. I added 75ml of the acid.

During the warming I got too aggressive with the heating in an effort to fully decompose the adduct to SA and SO2, forgetting to follow the direction

of “warming.” As a consequence I believe I lost 2-3g of product via steam distillation up the hood vent. I could visibly see that the volume of

yellow oil on the bottom of the flask had decreased. Warming the adduct in the water bath is shown below:

SA bisulfite adduct decomposition

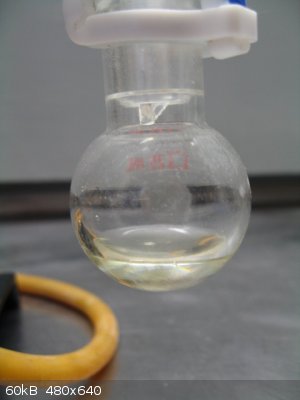

i. Extraction

The SA/water product was then extracted with 25ml x 15ml of DCM. The extract is shown drying overnight over anhydrous MgSO4 in the picture below:

SA in DCM being dryed

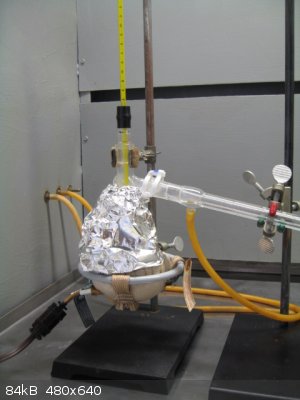

i. Distillation

The next day the DCM was removed by distillation. Following this with the pot heavily insulated with a fiberglass blanket shrouded in aluminum foil,

the SA was distilled. The product was captured that boiled in the range of 193-196°C. Literature value (Vogel) is 195-197°C. Pictures of the

distillation apparatus, the thermometer at product take-off, and the salicyaldehyde product are shown below:

SA distillation

SA distillation temperature

SA product

E. Results

My yield was a disappointing 6g. The yield would have been better if not for the losses described above. The expected yield (Vogel) is 12g. Even

this is only a 37% yield.

F. Conclusions

1. Salicylaldehyde can be successfully made using the Riemer-Tiemann reaction and Vogel’s procedure. My poor yield can certainly be much improved.

2. DCM can be successfully substituted for diethyl ether as the extractant in this synthesis. Other than its obvious advantages I think DCM gives

cleaner separations, and is quite recoverable by distillation.

3. My homemade overhead stirrer performed satisfactorily.

G. Discussion

My reasons for doing this synthesis are many: (1) I wanted to perform a complex synthesis involving relatively benign chemicals as I have been out

of the lab for ~3 months due to a health issue which has since been satisfactorily resolved, (2) I had 500ml of reagent grade phenol that I’ve had

for over 5 years without use, (3) I wanted to find out how well DCM could be substituted for diethyl ether for extraction, (4) I wanted to test out my

new stepper motor overhead mixer, and (5) JimmyMajesty’s work with aldehydes piqued my interest in isolating an aldehyde by sulfite adduct. Also I

wanted to perform a name reaction new to me. I found the Riemer-Tiemann mechanism to be fascinating; and carbenes are always fascinating.

Salicylaldehyde has a smell very similar to benzaldehyde, but with a little bite and is not as sweet or strong. One source said it smells of bitter

almond.

H. References

1. http://en.wikipedia.org/wiki/Reimer%E2%80%93Tiemann_reaction

2. Practical Organic Chemistry, 3rd edition, by Arthur I. Vogel, 1956 (see forum library)

Questions, comments, and suggestions are welcomed.

[Edited on 30-3-2015 by Magpie]

[Edited on 30-3-2015 by Magpie]

[Edited on 31-3-2015 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

That looks very interesting, Magpie, but I think I'll pass on trying it myself.

|

|

|

morganbw

National Hazard

Posts: 561

Registered: 23-11-2014

Member Is Offline

Mood: No Mood

|

|

Good job, it would take many of us more than one try, to get any product.

|

|

|

Loptr

International Hazard

Posts: 1348

Registered: 20-5-2014

Location: USA

Member Is Offline

Mood: Grateful

|

|

You are on of my inspirations in this hobby!

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thank you blogfast, morganbw and Loptr.

I hope JimmyMajesty tries isolating his acetaldehyde by sulfite adduct.

[Edited on 31-3-2015 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Crowfjord

Hazard to Others

Posts: 390

Registered: 20-1-2013

Location: Pacific Northwest

Member Is Offline

Mood: Ever so slowly crystallizing...

|

|

Did you only decompose the solid adduct? A fair amount tends to remain dissolved in the aqueous filtrate (see Len1's Illustrated Practical Guide for

benzyl chloride, benzal chloride, benzaldehyde, etc in prepublications). Could have been another contributor to your low yield. I'm away from my

notes, but in isolating 2,5-dimethoxy benzaldehyde from reaction solvent and starting compound (Beauveault aldehyde synthesis) via bisulfite adduct, I

think I actually got more aldehyde from the aqueous solution than the filtered solid.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

No, I did not. The adduct that slipped under the filter paper would have been in there too, along with the phenol, and a little alcohol/DCM wash. I

should have reviewed Len1's benzaldehyde synthesis.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

That is Great,

Magpie,i want to suggest another method

As you know Riemer-Tiemann is low yield method but o-formylation of phenols by mg has better yield.

Have you ever tried Mg-mediated o-formylation of phenols method?

also there is another interesting method according to Mg-mediated o-formylation of phenols.

I want to try it and will share the result:

| Quote: |

The One Pot Synthesis Salicylaldehyde Prepared by Reactive Grinding with Derivative Phenol and Paraformaldehyde in Absence Magnesium

Methoxide

A aromatic Phenol (0.1 mol), magnesium methoxide (5 gr ), and the mixture was grinding to 1 minute at room temperature. A slurry of paraformaldehyde

powder (4 gr) in under grinding was added in small portions over 2 min to the reaction mixture. Stirring was continued at r.t for 8 min, after which

added slowly to 10% sulfuric acid (20 ml g). The resulting mixture was stirred for 10 min, after which the aqueous layer was separated and extracted

with ethyl acetate (2 x 100 ml). The combined organic layers and extracts were washed with 10% sulfuric acid (20 ml) and water (20 ml) and evaporated

under reduced pressure to give the salicyaldehyde (Yield 85%)

http://dx.doi.org/10.13005/ojc/290445

|

and also below:

| Quote: |

Magnesium-mediated ortho-Specific Formylation and Formaldoximation of Phenols

2-Hydroxybenzaldehyde -Phenol (37.6 g, 0.4 mol) was

added to magnesium methoxide (259 g of 8 wt.% solution in

methanol; 20.7 g, 0.24 mol) and the mixture was heated to

reflux. Approximately half the methanol was distilled off and

toluene (300 g) was added to the residue. The azeotropic

mixture of toluene and methanol was removed by fractional

distillation, until the temperature of the reaction mixture rose to

95 "C. A slurry of paraformaldehyde powder (43.2 g, 1.44 mol)

in toluene (75 g) was added in small portions over 1 h to the

reaction mixture at 95 "C with concurrent removal of volatile

materials by distillation. Stirring was continued at 95 "C for 1 h,

after which mixture was cooled to 25 "C and added slowly to

10% sulfuric acid (450 g). The resulting mixture was stirred at

30-40 "C for 2 h, after which the aqueous layer was separated

and extracted with toluene (2 x 100 g). The combined organic

layers and extracts were washed with 10% sulfuric acid (50 g)

and water (50 g) and evaporated under reduced pressure to give the aldehyde 2a as a pale yllow oil (48.35 g, 84%)

Aldred, Robert; Johnston, Robert; Levin, Daniel; Neilan, James; Journal of the Chemical Society, Perkin Transactions 1: Organic and Bio-Organic

Chemistry (1972-1999); nb. 13; (1994); p.1823 - 1832

DOI: 10.1039/P19940001823

|

[Edited on 31-3-2015 by Waffles SS]

|

|

|

Loptr

International Hazard

Posts: 1348

Registered: 20-5-2014

Location: USA

Member Is Offline

Mood: Grateful

|

|

How sensitive are aldehydes to air oxidation? Any particular measures that must be taken during the procedure, or doing its storage? I know you

previously synthesized benzaldehyde using persulfate, and am curious if the oxidation potential is the same for both salicylaldehyde and benzaldehyde.

|

|

|

lullu

Hazard to Self

Posts: 51

Registered: 2-3-2012

Member Is Offline

Mood: No Mood

|

|

Very nice Magpie!

Is there any specific reason you liberated the aldehyde in acidic conditions, thereby forming SO2?

Or just because you can as you have one of the nicest fume hoods I've seen on here  ? ?

I would also recommend the Mg formylation as an alternative it is a breeze.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thank you waffles and lullu. I used the Reimer-Tiemann for the reasons stated in the "Discussion" section of my report. But thanks for the

information on o-formylation.

lullu, that is an interesting question about using acid for liberation of the aldehyde from the adduct. I've seen for other syntheses, and expected,

that this would be done with a base. I just followed the direction in Vogel in using the acid, 1M H2SO4.

Loptr, I can't say for sure for salicylaldehyde (yet) but for benzaldehyde it is surprisingly stable. I would expect SA to be similar. But for

butyraldehyde and propionaldehyde my experience is that they oxidize easily.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

Are you sure Benzaldehyde is stable in oxidation?

According to my experience it will oxidized almost fast with air oxygen .

Also it is suggested by different resource to distill it before use or wash it with Carbonate solution for get rid of Benzoic acid

Oxidation of Salicyldehyde depend on oxidation substance.

Usually Electron donating group(activating groups) make Benzaldehyde more stable in radical oxidation but for OH group i think we should test it.

[Edited on 31-3-2015 by Waffles SS]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I made my benzaldehyde some time ago and have used it at least 2 times since for successful syntheses. That's all I have to go on.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

NexusDNA

Hazard to Others

Posts: 104

Registered: 23-11-2013

Location: Brazil, under an umbrella

Member Is Offline

Mood: Liberated from cocoon

|

|

Excellent, Magpie! Thank you!

I'm interested in doing this preparation. I'll post here if everything goes ok.

Bromine, definitely bromine.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thank you Nexus.

After recovering the 2nd batch of DCM (40 mls) I gave it a sniff test (not recommended) for quality control before placing it in the mother supply

bottle. It had a sharp, nasty sting so I set it aside for later cleanup w/activated charcoal. After running it through the charcoal I checked again

with a sniff (not recommended) and - ouch - it had not changed. But this time I realized what it was: SO2!

Of course - it had been dissolved during the extraction following the adduct decomposition. So, I treated it with an aqueous CaCO3 slurry. This was

a mistake as the CaCO3 seemed to react with the DCM forming a gummy mess. It did get rid of the SO2 however, so I did recover about 20 mls. Na2CO3,

NaOH, or KOH, would probably have been a good choice.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Jimmymajesty

Hazard to Others

Posts: 153

Registered: 9-7-2009

Member Is Offline

Mood: No Mood

|

|

Hey Magpie,

Well done!

I tried to isolate the acetaldehyde as the bisulhite adduct.

It needs time for the formation and for the decomp also, also you can precipitate the bisulphite without the adduct if there is an ethanol carry over

and there is always some with the catalytic method. So I do not isolate the acetaldehyde rather use it as a gas, but if you need some more info on the

acetaldehyde adduct I surely can do some experiments for you

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks Jimmy. No, I have no plans to make acetaldehyde at this time. But I might in the future, as like I said before, for some reason I want to

make crotonaldehyde. I just wanted you to see how the adduct is used in case you wanted to use it to isolate your acetaldehyde or store it in powder

form.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

learningChem

Hazard to Others

Posts: 182

Registered: 21-7-2011

Member Is Offline

Mood: No Mood

|

|

Would the reaction work with cresol ? (yielding some kind of methyl aldehyde?)

|

|

|

CaptainPike

Hazard to Self

Posts: 68

Registered: 21-12-2012

Member Is Offline

Mood: No Mood

|

|

Magpie,

We love you – you make the absolute best OC Porn, ever!

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks, Captain.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

ronstark

Harmless

Posts: 37

Registered: 10-10-2016

Member Is Offline

Mood: No Mood

|

|

Did try the adduct for the first time to improve my chemistry. It was made according to Vogel's: 50g Sodium Bisulfite in 100mL water and 70mL EtOH.

Some chunks remained undissolved, but filtered to a clear solution. 50g Salicylaldehyde added to the solution and stirred 1h. The crystals were

filtered and the filtrate had a blue purplish colour. Is this normal? After the filtrate was dried, 90g SA adduct. 100mL 10% NaOH was added and

crystals begin to form on the bottom. The solutiom is reddish and on top oily drops, more like chicken fat. Can I saturate this with NaCl? Think I

will try with H2SO4 next time. Looks more clean on your photos. I did extract a portion with DCM and upon evaporation it was a red purple oil. It

seems very hard to extract that oily drops from the solution. Xylene is a better solvent?

[Edited on 9-2-2017 by ronstark]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I saw no colors after the formation of the adduct other than a slight yellowing of the final product.

I have no special insight into where your blue and red colors came from. My only guess would be impure product/reagents somewhere along the line.

There could be a reason for Vogel's specification of 1M H2SO4 instead of using NaOH for regeneration of the aldehyde.

I don't know if xylene would be a suitable solvent as it is completely non-polar. DCM and ether have some polarity, however, which would seem more

appropriate.

[Edited on 10-2-2017 by Magpie]

[Edited on 10-2-2017 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

UC235

National Hazard

Posts: 565

Registered: 28-12-2014

Member Is Offline

Mood: No Mood

|

|

Purplish color sounds like iron contamination to me with salicylic acid around.

I looked into the Reimer-Tiemann reaction a while ago for salicylaldehyde since I lack paraformaldehyde, but except for certain substrates, the yield

is quite terrible. The magnesium mediated approach is vastly superior.

Attachment: ReimerTiemannreview.pdf (1.4MB)

This file has been downloaded 1578 times

|

|

|

| Pages:

1

2 |