| Pages:

1

2

3

4

5 |

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

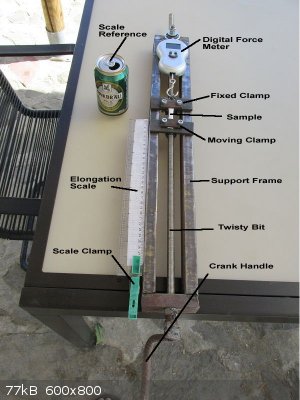

'ows about adding this jobbie into the mix :

Just €5 from the chinese shop !

So, when the 'twisty bit' gets turned, the rack stretches the subject, those scales measuring the diabolical stretchy forces unponst said subject.

It appears to have a kind of 'ratchet' function where it records the max pulling force.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Looking good!

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

As it is said, so shall it be.

Any clues pertaining to the actual Max distance stuff Can stretch ?

I got to pick some bits of steel out of the pile and cut 'em to length.

The 'twisty bit' is a metre long, so about 80cm is the max i can do.

Edit:

... without special effort.

[Edited on 4-6-2016 by aga]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  |

Any clues pertaining to the actual Max distance stuff Can stretch ?

[Edited on 3-6-2016 by aga] |

Acc. information upthread, elongation break is about 211 %. A specimen with active length of say 5 cm would stretch to about 15 cm and then snap.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Presenting: The StretchFast25

Tadaaa !

The sample gets clamped in, the crank turned to get the teensiest bit of tension in the sample, then the elongation scale is zeroed, the force scale

tared and the sample length measured, then start turning the handle until it snaps.

Here's a small rubber band before and after:-

Starting length of sample : 40mm

Distance travelled by the moving clamp at snapping point : 118mm

(i.e. snapped at total length 158mm)

The force scale keeps going into 'lock' so not sure what the Force was at snapping point (it locked at 0.09kg). Probably some feature to stop

fishermen lying about Weight as well as Length !

Will find out how that is disabled.

[Edited on 4-6-2016 by aga]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@aga:

That looks really great!

Make sure the top clamp is lubricated with respect to the sliding bars, to reduce friction errors.

Have you thought about the curing conditions of the Sugru?

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Found it - just press the Tare button for a while and it says 'L-Off' which means the lock function is disabled.

Start length: 29mm

Elongation: 62mm

Snap length: 91mm

Force: 0.36kg

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  | Found it - just press the Tare button for a while and it says 'L-Off' which means the lock function is disabled.

Start length: 29mm

Elongation: 62mm

Snap length: 91mm

Force: 0.36kg |

So:

$$E@B=\frac{91-29}{29} \times 100\:\text{%}=214\:\text{%}$$

For Tensile Strength you need to know the cross section A of the sample:

$$TS=\frac{F}{A}$$

With force F in Newton and A in m2.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Which cross-section ?

The one before it gets stretched or the one at the breaking point ?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

The Actual, Real TS is the one using the cross-section at breaking point. But for reasons of simplicity we use the one before it gets stretched

because that one is easy to measure.

Both are easily related anyway because rubber is basically incompressible: its density hardly changes when compressed or elongated.

If the sample had a cross-section A<sub>0</sub> and initial length L<sub>0</sub> then its volume is:

$$V=A_0L_0$$

Now we stretch it to L, its cross-section decreases to A:

$$V=AL=A_0L_0$$

So:

$$A=A_0\frac{L_0}{L}$$

Using that, the Real TS and the one calculated based on A<sub>0</sub> can be related easily.

[Edited on 4-6-2016 by blogfast25]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

These bands are a square section.

These digital vernier calipers say it's 1.34mm x 1.58mm, based on measurement at the point where there is a slight resistance to movement between the

jaws.

Not easy to measure this way, as the rubbery stuff obviously 'gives' when you try to clamp it.

How do they measure elastic stuff professionally ? Optics ?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  | These bands are a square section.

These digital vernier calipers say it's 1.34mm x 1.58mm, based on measurement at the point where there is a slight resistance to movement between the

jaws.

Not easy to measure this way, as the rubbery stuff obviously 'gives' when you try to clamp it.

How do they measure elastic stuff professionally ? Optics ? |

We used to use a digital vernier type measurement, with a 'soft touch'. Rubbers inevitably give, so it's a bit approximate.

Those values and the 0.36 kg give TS = 1.7 MPa. That sounds a little low even for a 'cheap and dirty' rubber band but it is what it is, I guess...

Try one of these wider 'natural colour' rubber bands for parcelling etc?

[Edited on 4-6-2016 by blogfast25]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

It is safe to assume that several <strike>victims</strike> samples will be tested over the next few days.

Need to get a feel or the process before the shugargoo arrives.

Edit :

On which point, how would you like the Victims treated before being subjected to the Rack ?

The usual Acid Bath, or perhaps some fiendishly exotic scheme ?

[Edited on 4-6-2016 by aga]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  |

It is safe to assume that several <strike>victims</strike> samples will be tested over the next few days.

Need to get a feel or the process before the shugargoo arrives.

Edit :

On which point, how would you like the Victims treated before being subjected to the Rack ?

The usual Acid Bath, or perhaps some fiendishly exotic scheme ?

|

As you said, first get a feel for the 'Rack'.

Analyse several mundane samples.

Get a feel for repeatability by analysing the same sample several times.

Even with professional equipment:

https://www.youtube.com/watch?v=9N5SS8f1auI

... expect considerable spread on the TS and E@B values, for a given material.

[Edited on 5-6-2016 by blogfast25]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

The pros clearly have Slidy bits on show, yet at 0:51 in the video a small Twisty bit is visible at the bottom-left of the machine.

I suspect there's a Big Twisty bit hidden in the casing.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

The stuff arrived today.

Data from the packaging ...

Storage: 21 C or less. Keeping unopened packs in the fridge makes them last up to 3 times longer .

Cures up to 3mm thick in 24 hours

Temperature resistant up to 180 C, down to -50 C

'salt water proof'

an electrical insulator.

It turns into a flexible silicone rubber

Contains:-

Methyltris(methylethylketoximine)silane

3-aminopropylethoxysilane

--------------------------------

It feels like wet blu-tack, very similar to putty.

The smell is unusual, yet not totally unfamiliar.

I can imagine computers inhaling it to give then an 'all 1111s' high.

After a few big whiffs of it there was a noticeable feeling of it banging about in my sinuses. This settled after 5 minutes to become a dull ache

where my jaw pivots on the right hand side.

The solvent sticks to skin (mine at least) as does a very small fraction of the blue colouring.

It has been flattened out into a rough dumb-bell shape and left to cure.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@aga:

Might be better to roll pin a small squarish slab of uniform thickness (2 - 3 mm, to be measured accurately post-cure), cure it and then cut out

dumbbells with a pair of scissors and a pattern?

[Edited on 6-6-2016 by blogfast25]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Yep. Might be, but i didn't.

Probably best to just open the pack, let it cure, then stretch the feck out of it.

Is there any reason for the cutting-out-a-shape part ?

e.g. an exact starting thickness/width ?

What does 'roll pin' mean ?

To me that is a (usually) small steel cylinder with a bit missing.

[Edited on 6-6-2016 by aga]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  |

1. Probably best to just open the pack, let it cure, then stretch the feck out of it.

2. Is there any reason for the cutting-out-a-shape part ?

3. e.g. an exact starting thickness/width ?

4. What does 'roll pin' mean ?

To me that is a (usually) small steel cylinder with a bit missing.

|

1. Not if you want values (TS and E@B) that are representative.

2. Just sounds easier to make reproducible shapes that way.

3. You'll always have to measure thickness after curing. Rubber is a visco-elastic material.

4. Sorry: rolling pin. Roll the Sugru like you would tart dough.

[Edited on 7-6-2016 by blogfast25]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

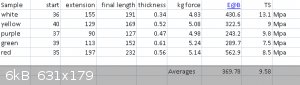

Had a bash at the stretchy-snappy-o-meter today with short lengths of heat-shrink tubing.

Results:

The cured sugru stuff then got it's turn, and came out at E@B = 75.2%, TS=1.6MPa

What to do with it next ? Hmm ...

C'mon. Place yer bets !

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  | Had a bash at the stretchy-snappy-o-meter today with short lengths of heat-shrink tubing.

The cured sugru stuff then got it's turn, and came out at E@B = 75.2%, TS=1.6MPa

|

The results for the heat-shrink tubing 'sound right'.

But E@B = 75 % for the Sugru sounds very low. I wonder if your stuff has been fully cured. The curing chemical reactions are slow at

RT. To complete cure, we used to add a short so-called 'post cure' for RT cured elastomers. In the case of Sugru, a mere 15 min @ 180 C (in a domestic

oven) should complete the curing to a 100 % completion.

Nice work!

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

El Sugrero has been curing for a few days, and RT at the mo is around 36C + during the day.

Will zap the next batches in the oven.

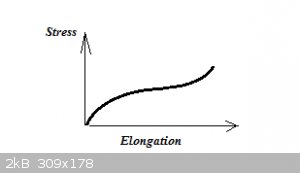

It feels quite odd, in that when you stretch it by hand, it has a range in which it stretches linearly, then at a certain point it is as if some

internal fibres have gone as far as they can, and it resists further stretching.

The sulphuric sample is going green ...

What next ? Pre-treat, post-treat, stretchy-snappy ?

Burny, freezy ?

Edit:

7 samples left

[Edited on 12-6-2016 by aga]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  |

It feels quite odd, in that when you stretch it by hand, it has a range in which it stretches linearly, then at a certain point it is as if some

internal fibres have gone as far as they can, and it resists further stretching.

|

Ideal elastomers have a stress v elongation curve like this:

It fits your observation.

Apart from any chemical resistance tests, it could be interesting to stretch a sample at say 50 % for 24 h, then see how much it recovers on release

That gives an idea of creep, an important property in sealing applications.

[Edited on 12-6-2016 by blogfast25]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

So, make Two identical samples, stretch one until it snaps, measure elongation, then stretch the second one to 50% of that for 24hrs, then see how

long it is when released.

OK.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  |

So, make Two identical samples, stretch one until it snaps, measure elongation, then stretch the second one to 50% of that for 24hrs, then see how

long it is when released.

OK. |

Yup. From the residual elongation and initial length, calculate the Tension Set, the same way you calculate the E@B.

Also interesting: extend to say 50 % then stop extending and monitor stress. As a visco-elastic material its stress will reduce in time, aka

stress relaxation.

|

|

|

| Pages:

1

2

3

4

5 |