KoiosPhoebus

Hazard to Self

Posts: 51

Registered: 23-1-2023

Member Is Offline

|

|

Help with crystallising monopotassium glutamate

Hi all,

I'm trying to prepare some monopotassium glutamate using glutamic acid which I extracted from MSG, and potassium hydroxide. I'm interested in

comparing the taste of MSG to that of monopotassium glutamate, among other things.

While the reaction is successful (with a pH roughly in the same range as an equimolar solution of my starting MSG), I have been unable to crystallise

the resulting potassium glutamate. Attempts at evaporation on my hotplate eventually result in a gooey sludge (think glycerol at 20 deg C); if I try

to crank the heat up to max, it yields a slightly yellowed gel-like layer.

Other things I've tried:

Variations on cooling the solution. Either reacting the glutamic acid + potassium hydroxide at room temperature,

then putting it into the freezer, or reacting the glutamic acid and potassium hydroxide at high temperatures, evaporating to the syrup state, then

putting it into the freezer. In all cases, the result is a more viscous (or sometimes gel-like) clear sludge.

Adding the solution to ethanol. If the potassium glutamate solution is sufficiently concentrated, the result is two separate

layers, a slightly cloudy layer of ethanol, and a clear layer of water (and what I presume is the potassium glutamate). If it's more dilute, I end up

with a completely clear solution; continuous stirring for 5 hours has not produced any crystallisation (idea from this paper: https://doi.org/10.1080/00021369.1964.10858277; unfortunately I don't have methanol on hand right now, so I'll need to repeat that with methanol).

Increasing the water:ethanol ratio up to 1:4 has only resulted in layer separation where a lower ratio (with same volume of water) did not result in

layer separation.

Adding acetone into the solution. A similar layer-separation effect is seen as with the ethanol; but if the mixture is stirred

enough, a white precipitate of glutamic acid (pH ~ 2 when filtered off and re-dissolved) is seen.

Adding a pile of MSG crystals to saturated solution. I was hoping that the MSG would act as seed crystals to initiate

crystallisation (like in this patent: https://patents.google.com/patent/CN101863789A/en), but unfortunately nothing has happened.

Only adding a very small amount of distilled water to the reactants (3 - 4 mL). The result is complete dissolution of the

potassium glutamate, likely due to residual water in the potassium hydroxide + the water generated by the reaction. As the reaction proceeds, it

acquires the syrupy viscosity again (I suppose, at least this tells me that it's not my heating that's causing the issue?)

Attempting to remove the water using an n-propanol azeotrope. Idea from this patent: https://patents.google.com/patent/US2829162. This seems to have been the most successful in that it managed to get the solution down to a white

sludge (instead of the clear sludge that standard evaporation resulted in). Unfortunately it still didn't produce crystals of any kind. Additionally,

the combination of the alcohol-aqueous KHGlutamate layer separation mentioned above plus the resulting sludge means that when I get to the final

stages, I end up boiling off n-propanol without removing much of the water.

This seems to be a common theme with organic acid/metal complexes (see attempt II here: https://www.sciencemadness.org/whisper/viewthread.php?tid=15...). Does anyone have any experience trying to isolate such compounds and would be

able to advise me on how to go about crystallising monopotassium glutamate? Thanks in advance for any help!

[Edited on 2-8-2023 by KoiosPhoebus]

|

|

|

Lionel Spanner

Hazard to Others

Posts: 163

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

Can you remove the water under vacuum?

I find that helps a lot when removing water from highly soluble compounds, as lowers the water's boiling point and reduces the compound's solubility.

|

|

|

SplendidAcylation

Hazard to Others

Posts: 196

Registered: 28-10-2018

Location: Starving in some deep mystery

Member Is Offline

Mood: No one I think is in my tree.

|

|

I like your systematic approach to this problem, it reminds me of a similar problem I have encountered many times when dealing with amine salts.

Point 1 is particularly relatable, many times I have put things in the freezer in the hope that they would crystallize from syrup to solid crystals,

but it hasn't worked once!

The last refuge of the chemist trying to crystallize a syrupy salt is vacuum desiccation.

If you have a "one-way" desiccant like phosphorus pentoxide, then placing your syrupy substance in a sealed container with the phosphorus pentoxide is

bound to work, however doing it in a vacuum will be quicker.

Sodium hydroxide granules are also a very good desiccant, so you could try desiccating your product in a vacuum over sodium hydroxide.

[Edited on 3-8-2023 by SplendidAcylation]

|

|

|

Bedlasky

International Hazard

Posts: 1219

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

Quote: Originally posted by SplendidAcylation  |

Sodium hydroxide granules are also a very good desiccant, so you could try desiccating your product in a vacuum over sodium hydroxide.

[Edited on 3-8-2023 by SplendidAcylation] |

KOH is even better. NaOH do the work, but from my practice KOH do it better.

|

|

|

KoiosPhoebus

Hazard to Self

Posts: 51

Registered: 23-1-2023

Member Is Offline

|

|

Thanks for all the advice! I'll try vacuum desiccation on a sample and report

back.

Quote: Originally posted by Bedlasky  | Quote: Originally posted by SplendidAcylation  |

Sodium hydroxide granules are also a very good desiccant, so you could try desiccating your product in a vacuum over sodium hydroxide.

[Edited on 3-8-2023 by SplendidAcylation] |

KOH is even better. NaOH do the work, but from my practice KOH do it better. |

Unfortunately, the only potassium hydroxide I have access to is 90%, with the

majority of the remainder being water. Does that also work as a desiccant?

[Edited on 5-8-2023 by KoiosPhoebus]

|

|

|

Bedlasky

International Hazard

Posts: 1219

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

I don't know, NaOH with less water would be probably better.

|

|

|

KoiosPhoebus

Hazard to Self

Posts: 51

Registered: 23-1-2023

Member Is Offline

|

|

Update:

I've tried a couple of things to crystallise the monopotassium glutamate:

Vacuum desiccation: I placed the syrupy solution of monopotassium glutamate into a vacuum desiccator, over a

separate dish of small sodium hydroxide pearls, then pulled a vacuum and left it. Every few hours, I came in to swap the sodium hydroxide out for a

fresh batch.

The vacuum desiccation attempt has been running for three days now and crystallisation has been minimal.

There's a few, very tiny crystals at the bottom of the sludge, but the sludge remains. The vacuum achieved was about -560 mmHg (or -74.6 kPa) - I'm

not sure if that could have been the issue, in that it was insufficient to pull the water out of the sludge?

For the vacuum desiccation, I used a 150 mm amber vacuum desiccator, and plugged it into an LE-22C vacuum pump (image below). All parts were greased

with high-vacuum silicone grease prior to the experiment.

A Swedish website gives the following specs for the vacuum pump:

Ultimate (not absolute) vacuum: "10 mbar, (1000 Pa)."

Flow rate: "5 l/min."

The vacuum pump is just a couple of months old, but maybe something's up with it and it's unable to pull a near-perfect vacuum? I still would have

thought that three days at reduced pressure would be enough time to pull water out of the solution.

Microwave heating: After I pulled out the sludge from the vacuum desiccator, I decided to try microwaving it to see what would

happen. My reasoning was that since the sludge was probably a mix of water and potassium/glutamate ions, the microwave might excite the water

molecules enough that they would evaporate from solution and leave the potassium glutamate behind.

Unfortunately, the mixture burned.

I pulled the dish out of the microwave and let it sit to cool. After a period of time, I heard cracks and thought to myself: oh well, there goes the

dish.

Surprisingly, however, it wasn't the dish that cracked, but the (now much more solid) stuff inside it.

I thought that perhaps the compound had crystallised, but when I touched it, it was still sticky to the touch. After some time left out, it began to

reacquire its gooey characteristic and became more slime-like to the touch, at which point I tossed it out.

I'm going to see if microwaving at a lower power setting would force out enough water that I can collect monopotassium glutamate crystals, of some

sort. In the meantime, if anyone has any ideas for how to crystallise this compound, I'd love to hear them!

(In particular, if you've successfully crystallised a similar salt of a complexing agent - e.g. potassium gluconate, potassium citrate - I'd be

interested in hearing about how you accomplished it.)

|

|

|

fusso

International Hazard

Posts: 1922

Registered: 23-6-2017

Location: 4 ∥ universes ahead of you

Member Is Offline

|

|

Or, just use it as is, since you're just gonna taste it? Water solution shouldn't have different taste than the solid.

|

|

|

Boffis

International Hazard

Posts: 1836

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Hi Phoebus. The clue is in the name, glutamic acid from glutinous. Glutamic acid and glutamates tend to be very soluble and form glutinous syrups on

evaporation. I faced this recently with pipecolic acid, the answer was eventually to precipitate the hydrochloride. In your case this isn't really

applicable but you might be able to evaporate it on water bath to a thick syrup and then triturating the syrup with methanol or ethanol. Try a small

quantity first, once you have crystals you can use thee to seed the syrup. But remember that viscous media crystallise more slowly than thin liquids

(think of honey for example). So sometimes you need to have seed crystals to stir in to the syrup.

|

|

|

SplendidAcylation

Hazard to Others

Posts: 196

Registered: 28-10-2018

Location: Starving in some deep mystery

Member Is Offline

Mood: No one I think is in my tree.

|

|

@KoiosPhoebus I'm somewhat confused about your vacuum desiccation procedure.

You said you swapped the NaOH every three hours, did you do this continuously for 3 days, so like twenty swaps?

Furthermore, did you run the pump continuously?

Regarding my second point, there isn't any need to run the pump continuously, as the desiccant is there to absorb the water vapour, so you don't need

to continuously suck it away with the pump, just evacuate it as much as you can, then seal it.

As for swapping the desiccant, this is not a good idea!

When you seal the desiccator, it will take some time for the moisture in the air to be absorbed by the desiccant, it would probably take hours; only

after this point would your compound begin to desiccate.

If you keep opening it, all you're doing is drying the air inside, the compound will never get a chance to dry.

You need to put the glutamate, and the NaOH, in the desiccator, evacuate, seal it, and leave it for a day at the very least before opening it, then

see if it has decreased in weight.

I may be wrong, just my two cents :p

|

|

|

Lionel Spanner

Hazard to Others

Posts: 163

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

Are you in a position to try removing the water by vacuum distillation?

(This was what I meant in my original post, which I now realise was ambiguous.)

|

|

|

KoiosPhoebus

Hazard to Self

Posts: 51

Registered: 23-1-2023

Member Is Offline

|

|

Quote: Originally posted by Boffis  | | Hi Phoebus. The clue is in the name, glutamic acid from glutinous. Glutamic acid and glutamates tend to be very soluble and form glutinous syrups on

evaporation. I faced this recently with pipecolic acid, the answer was eventually to precipitate the hydrochloride. In your case this isn't really

applicable but you might be able to evaporate it on water bath to a thick syrup and then triturating the syrup with methanol or ethanol. Try a small

quantity first, once you have crystals you can use thee to seed the syrup. But remember that viscous media crystallise more slowly than thin liquids

(think of honey for example). So sometimes you need to have seed crystals to stir in to the syrup. |

Thanks for the suggestion! Unfortunately triturating the syrup with ethanol doesn't

seem to be any different from when I tried adding ethanol to the saturated solution of potassium glutamate.

I know someone who works in a university laboratory, and they've helped me to place a dish of potassium glutamate solution into a 60 deg C oven -

hopefully, after a week or two, some crystallisation will occur. Unfortunately this lab is a biology lab, so they don't have rotary evaporators or

similar tech.

Quote: Originally posted by SplendidAcylation  | @KoiosPhoebus I'm somewhat confused about your vacuum desiccation procedure.

You said you swapped the NaOH every three hours, did you do this continuously for 3 days, so like twenty swaps?

Furthermore, did you run the pump continuously?

Regarding my second point, there isn't any need to run the pump continuously, as the desiccant is there to absorb the water vapour, so you don't need

to continuously suck it away with the pump, just evacuate it as much as you can, then seal it.

As for swapping the desiccant, this is not a good idea!

When you seal the desiccator, it will take some time for the moisture in the air to be absorbed by the desiccant, it would probably take hours; only

after this point would your compound begin to desiccate.

If you keep opening it, all you're doing is drying the air inside, the compound will never get a chance to dry.

You need to put the glutamate, and the NaOH, in the desiccator, evacuate, seal it, and leave it for a day at the very least before opening it, then

see if it has decreased in weight.

I may be wrong, just my two cents :p |

I did leave the pump running continuously, and the shortest time between NaOH swaps

was 3 hours, depending on when I had time (there was one day when I didn't swap the NaOH at all).

I've noticed that if the pump isn't running continuously, after about half an hour, the vacuum is lost. This is despite all parts being greased with

high-vacuum silicone grease, and the stopcock being closed.

Thanks for the other advice - I might try it again as per your instructions. I will say that when I placed a dish of non-saturated KHGlutamate

solution into the desiccator (non-viscous), after the desiccation it did become the viscous solution (with what appears to be tiny crystals at the

bottom).

Quote: Originally posted by Lionel Spanner  | Are you in a position to try removing the water by vacuum distillation?

(This was what I meant in my original post, which I now realise was ambiguous.) |

Ah, unfortunately, no. I don't have a vacuum distillation set - been meaning to get

one, but have yet to get around to it.

I might look into preparing calcium diglutamate instead; it might be easier to

crystallise than monopotassium glutamate as I've seen calcium diglutamate sold as flavour enhancer in the past. I'm surprised that monopotassium

glutamate is significantly harder to crystallise than monosodium glutamate - I would've thought that the similar cations would have resulted in

similar crystallisation.

|

|

|

KoiosPhoebus

Hazard to Self

Posts: 51

Registered: 23-1-2023

Member Is Offline

|

|

Isolating calcium diglutamate

Quote: Originally posted by Boffis  | | Hi Phoebus. The clue is in the name, glutamic acid from glutinous. Glutamic acid and glutamates tend to be very soluble and form glutinous syrups on

evaporation. I faced this recently with pipecolic acid, the answer was eventually to precipitate the hydrochloride. In your case this isn't really

applicable but you might be able to evaporate it on water bath to a thick syrup and then triturating the syrup with methanol or ethanol. Try a small

quantity first, once you have crystals you can use thee to seed the syrup. But remember that viscous media crystallise more slowly than thin liquids

(think of honey for example). So sometimes you need to have seed crystals to stir in to the syrup. |

Boffis, thanks for this piece of advice! This ended up working with calcium

diglutamate (haven't tried it with monopotassium glutamate yet).

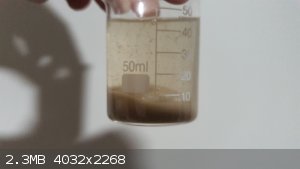

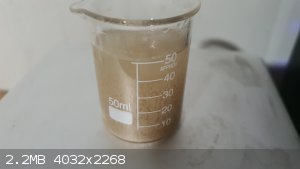

With calcium diglutamate, I added 17.2 g of L-glutamic acid to 3.82 g of calcium hydroxide. Both were added in slight excess due to impurities. I

determined the purity of glutamic acid by titrating with sodium hydroxide until it matched the pH of an equimolar solution of monosodium glutamate,

while I simply used the manufacturer's purity data on calcium hydroxide.

The impurities were pretty clearly visible; after all of the calcium hydroxide and glutamic acid had dissolved, a small amount of discoloured

flocculent solid remained.

I'm a little puzzled as to what the impurity might be. It definitely came from the calcium hydroxide; the same glutamic acid dissolved in potassium

hydroxide produced no flocculent precipitate, and the same flocculent precipitate was produced when reacting the calcium hydroxide with glycine.

Normally, the most common impurities in calcium hydroxide are iron oxides, aluminum oxides, or similar; these impurities should have dissolved in the

glutamic acid.

After some heating at around 50 deg C, the solution became thick and formed a thin upper layer like cling wrap. Previous attempts at heat-drying the

calcium diglutamate syrup had failed, so instead I let the syrup cool to room temperature. Once it had, I added about 100 mL of ethanol and began

poking and swirling the solution around. While it initially remained as a free-flowing liquid bilayer, after some time it became more viscous until it

eventually became an off-white goo with the consistency of sticky play-dough.

As it hadn't crystallised, I wasn't sure if the trituration had worked. I was initially going to toss it out, but I thought - what the heck, I'll try

drying it, the worst that happens is that I end up with the liquid calcium diglutamate goo again. After drying, it formed a surprisingly hard crust

which I scraped off and pulverised to form a powder.

About 15.2 g of calcium diglutamate was obtained. The % yield is difficult to ascertain as calcium diglutamate can be crystallised as either

anhydrous, monohydrate, dihydrate or tetrahydrate. The % yield is hence between 91.5% to 75.2% depending on the degree of hydration of the product. I

doubt it's 90+% as some crust was stuck on the crystallising dish (plus minor losses during transfer from dish > mortar/pestle > dish >

container).

Thanks once again Boffis for your advice! I will try the same method with monopotassium glutamate and see if it works.

|

|

|

KoiosPhoebus

Hazard to Self

Posts: 51

Registered: 23-1-2023

Member Is Offline

|

|

Something which might be relevant to the preparation of monopotassium glutamate:

Recently, I tried to prepare an aqueous solution of monopotassium glutaminate (the potassium salt of L-glutamine, which has an amide group instead of

a carboxyl group in its side chain). To prepare this, I added 31.2 g of L-glutamine to a small amount of water, then added 13.3 g of 90% potassium

hydroxide.

Within a short period of time, ammonia began to be evolved from the solution (a niche way of producing ammonia from sports supplement L-glutamine?).

After doing some research, apparently L-glutamine cyclizes at high pH and temperature to form L-pyroglutamic acid (https://doi.org/10.1021/bp00002a005), with loss of ammonia.

The interesting thing is that L-glutamic acid can undergo the same reaction, but instead of producing ammonia, it does so with loss of a water

molecule. Since potassium hydroxide is much more soluble than glutamic acid, it's plausible that the pH of the solution would start out very high

(with an associated jump in temperature as KOH dissolves). During the short period of time (1 minute+) before all the glutamic acid dissolves, it's

plausible that some of the glutamic acid cyclizes to pyroglutamic acid, which may influence the properties of the solution. Without analytical

chemistry, there would be no way to tell how much of the glutamic acid cyclizes.

|

|

|

Tsjerk

International Hazard

Posts: 3022

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

The impurity in the calcium hydroxide is probably calcium carbonate. Calcium hydroxide absorbs CO2 from the air, as does potassium hydroxide, but the

difference is the solubility of the formed carbonates.

|

|

|

KoiosPhoebus

Hazard to Self

Posts: 51

Registered: 23-1-2023

Member Is Offline

|

|

Quote: Originally posted by Tsjerk  | | The impurity in the calcium hydroxide is probably calcium carbonate. Calcium hydroxide absorbs CO2 from the air, as does potassium hydroxide, but the

difference is the solubility of the formed carbonates. |

While there's almost certainly some calcium carbonate in there, I think it's

unlikely that the flocculent solid is calcium carbonate. Firstly, calcium carbonate is white, not the weird shade of brown that the impurity was.

Secondly, calcium carbonate would dissolve in a solution of glutamic acid, as glutamic acid is relatively acidic at saturation (pH ~ 2) and the

glutamate anion is a chelator of calcium. This is especially the case in an acidic solution (the 1:2 ratio of calcium to glutamic acid).

|

|

|

|