Deathunter88

National Hazard

Posts: 508

Registered: 20-2-2015

Location: Beijing, China

Member Is Offline

Mood: No Mood

|

|

Preparation of Neodymium Sulfate from Magnets

Extracting Neodymium From Magnets

By: Deathunter88

Abstract:

There are many types of magnets in wide use, but currently the strongest permanent magnets are neodymium magnets, which are made of a sintered powder

of an alloy made from neodymium, iron, and boron with the formula Nd2Fe14B. Thus, this makes it a convenient source of neodymium for the amateur

chemist.

Theory:

The separation of the neodymium from the iron and boron occurs in a few different steps. First, the magnet is dissolved in some dilute sulfuric acid

to form iron and neodymium sulfate. Meanwhile, the elemental boron is left behind since it is not soluble in dilute acid. Then the mixture is heated

to take advantage of the inverse solubility of neodymium sulfate. While most substances (including iron sulfate) are more soluble at high

temperatures, neodymium sulfate is unique in that its solubility decreases with increasing temperature. As the solution of the two sulfates is heated,

the neodymium sulfate crystallizes out.

Equipment:

Hotplate

Electronic mass balance

100ml graduated cylinder

250ml beaker

150mm crystallizing dish

Buchner funnel

Vacuum pump

Vacuum filtration flask

Blowtorch

#120 Sandpaper

Chemicals:

Neodymium magnet (Acid amount is given for a 50.00g magnet)

300ml dilute sulfuric acid ~30% (I used battery acid)

Distilled water

Procedure:

1. The magnet is heated strongly with the blowtorch until the curie temperature is reached and all magnetism is destroyed.

2. The Ni-Cu-Ni coating on the magnet is removed using the sandpaper in order to allow the acid to better attack the metal.

3. 200ml of the sulfuric acid is measured out using the graduated cylinder and poured into the beaker.

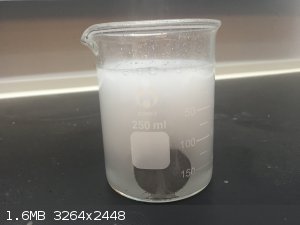

4. The magnet was placed into the acid and immediately a vigorous reaction is observed with plenty of effervescence.

5. The beaker is allowed to sit overnight for the magnet to dissolve. (The magnet can also be broken into chunks to speed up this step)

6. After sitting overnight, the liquid is poured off and another 100ml of sulfuric acid is added to the beaker to dissolve the remainder of the

magnet.

7. After again sitting overnight, the entire magnet should be completely dissolved, but if this is not the case repeat the procedure of adding acid

and pouring off the solution.

8. Crystals of iron sulfate that have formed inside the beaker are dissolved using 100ml of distilled water.

9. All of the solutions are combined and a vacuum filtration is performed to remove the insoluble boron particles.

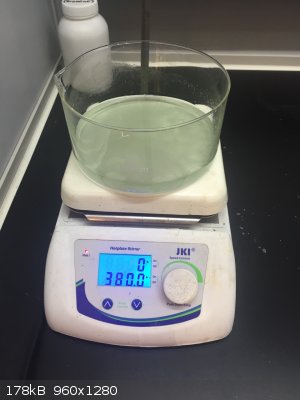

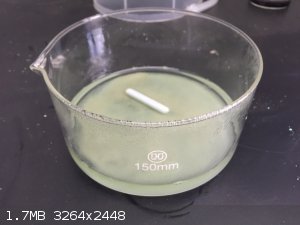

10. The filtrate is poured into the crystallizing dish which is evaporated on the hotplate set to 120˚C (the solution cannot be boiled since bumping

is a severe issue).

11. After 100ml of the solution has evaporated, the solution is vacuum filtered while hot to remove the neodymium sulfate that has precipitated out.

12. The neodymium sulfate is washed with some boiling water to remove the last traces of iron sulfate.

13. The remainder of the solution is again placed onto the hotplate until a further 100ml of water has evaporated and the filtering procedure is

repeated.

14. A third evaporation and filtering of the solution is performed just like the previous ones to recover the remainder of the neodymium sulfate.

15. After three crystallizations there is very little neodymium sulfate still in solution and so no further recovery is performed.

Results:

The first crystallization yielded 6.83g of product, the second crystallization yielded 9.37 grams of product, and the third crystallization yielded

3.60g of product. This totals to 19.80 grams of product total. (Right filter paper is 1st crystallization, vial is 2nd crystallization, left filter

paper is 3rd crystallization)

According to the formula stated above, the molar mass of "neodymium magnet" is (144.24*2)+(55.85*14)+(10.81*1)=1081g/mol. Thus, the 50.00g of magnet

that I used is 0.04625 moles, and since each mole of "neodymium magnet" contains 2 moles of neodymium, there should be a theoretical 0.09251 moles of

neodymium in the magnet. One mole of neodymium sulfate contains 2 moles of neodymium so a maximum theoretical 0.04625 moles of neodymium sulfate could

have been produced. One mole of neodymium sulfate octahydrate has a mass of 720.794 grams so the theoretical yield is 33.34 grams. The yield of this

experiment is 19.80 grams which is a 59.39% yield. The reason for this mediocre yield is that at first I attempted to boil down the solution which

resulted in major losses from bumping. Otherwise, the yield would probably have been higher.

Conclusion:

I feel that this was a pretty successful extraction and that the final product is reasonably pure. However, each crop of crystals is slightly

different. The first crystallization resulted in a fluffy powder that is less crystalline compared to the second crop. The second crop is the most

crystalline and the densest, while the last crop seems to be a mix of the first two. This confuses me and suggests that a recrystallization may be

needed.

|

|

|

DFliyerz

Hazard to Others

Posts: 241

Registered: 22-12-2014

Member Is Offline

Mood: No Mood

|

|

Beautiful crystals! I'm glad that someone finally posted a procedure, seeing as the other really good one on versuchschemie is gone.

|

|

|

ficolas

Hazard to Others

Posts: 146

Registered: 14-5-2016

Member Is Offline

Mood: No Mood

|

|

Thaks for this! I was about to do the same thing, but working blind with my small knowledge in chemistry would be bad, so I was going to ask if my

procedure was right, guess I no longer need to!

I failed at the separating the neodymium and iron sulfates part, I didnt know about the solubility of neodymium sulfate decreasing with temperature.

Do you guys know any source of praseodymium? I would also like to get some praseodymium sulfate

[Edited on 2-6-2016 by ficolas]

[Edited on 2-6-2016 by ficolas]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Great write-up !

Why destroy the magnetism before dissolution ?

When i tried this i got a similar-coloured powder, and let the magnet go out "with it's boots on".

Edit:

| Quote: | | each crop of crystals is slightly different |

This tends to be the case with crystals.

The precise mix of product/contaminants, ratio of product/contaminant/solvent, speed of cooling etc all affect how the crystals grow.

A recent batch of sodium sulphate came out as saw-toothed spikes, fine crystals and sheets, all from the same original batch.

[Edited on 2-6-2016 by aga]

|

|

|

Hegi

Hazard to Others

Posts: 199

Registered: 27-9-2013

Member Is Offline

Mood: No idea.

|

|

Very nice write-up. I´ll do this in near future! I am also interested in the question aga wrote. What is a purpose of destroying magnetism?

Our webpage has been shut down forever cause nobody was willing to contribute. Shame on you all!!!

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Nice write up and nice looking product.

But I'd strongly advise checking it for Fe (e.g. with some peroxide and KSCN or NH4SCN). Fe and Nd aren't that easily separated 100 %. A

certain degree of co-precipitation/co-crystallisation is hard to avoid.

[Edited on 2-6-2016 by blogfast25]

|

|

|

Deathunter88

National Hazard

Posts: 508

Registered: 20-2-2015

Location: Beijing, China

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  | Nice write up and nice looking product.

But I'd strongly advise checking it for Fe (e.g. with some peroxide and KSCN or NH4SCN). Fe and Nd aren't that easily separated 100 %. A

certain degree of co-precipitation/co-crystallisation is hard to avoid.

[Edited on 2-6-2016 by blogfast25] |

Yeah I need to check it for iron contamination, but I have to order some KSCN first.

|

|

|

Deathunter88

National Hazard

Posts: 508

Registered: 20-2-2015

Location: Beijing, China

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Hegi  | Very nice write-up. I´ll do this in near future! I am also interested in the question aga wrote. What is a purpose of destroying magnetism?  |

I guess you don't NEED to destroy the magnetism, but it makes working with the magnets a lot easier. These magnets are very strong and if you aren't

careful you will get blood blisters or maybe even broken fingers. The magnet I used has a pull force of 40lb based on this calculator by K&J magnetics. Also, if you plan to smash the magnet with a hammer you can't have the magnet sticking to the hammer.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

These are very good reasons to demagnetise.

Thanks !

|

|

|

j_sum1

Administrator

Posts: 6231

Registered: 4-10-2014

Location: Unmoved

Member Is Offline

Mood: Organised

|

|

Also getting the nickel coating off is tricky when it is magnetic.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Nice writeup. I feel obliged to link to the long-running thread on separating Nd from these magnets, here: http://www.sciencemadness.org/talk/viewthread.php?tid=14145

All of the questions in this thread are answered there. It's a long read, but well worth it.

I initially used the inverse-solubility approach for separation, but it was very tedious and I could never get that last bit of Nd out. A much better

method, pioneered by blogfast, is to use double salts. Adding solid potassium sulfate crashes out a very insoluble K-Nd double salt, affording a

quick, easy, and near-complete separation from iron.

Finally if you haven't tried it, make a solution of an Nd salt and look at it under different lighting. The color changes dramatically between

sunlight, incandescent bulb, short fluorescent tube lights, and large fluorescent tube lights.

|

|

|